With the global energy structure transitioning to low carbon, green hydrogen energy is becoming a key strategic direction. Hydrogen production from water electrolysis has attracted much attention due to its zero-carbon emission advantage, in which the electrolyzer, as the core equipment, puts high demands on the selection of materials. As an important pressure-bearing and sealing structure of the electrolyzer, the pole frame needs to operate stably for a long period of time in high temperature, high pressure and corrosive environment.

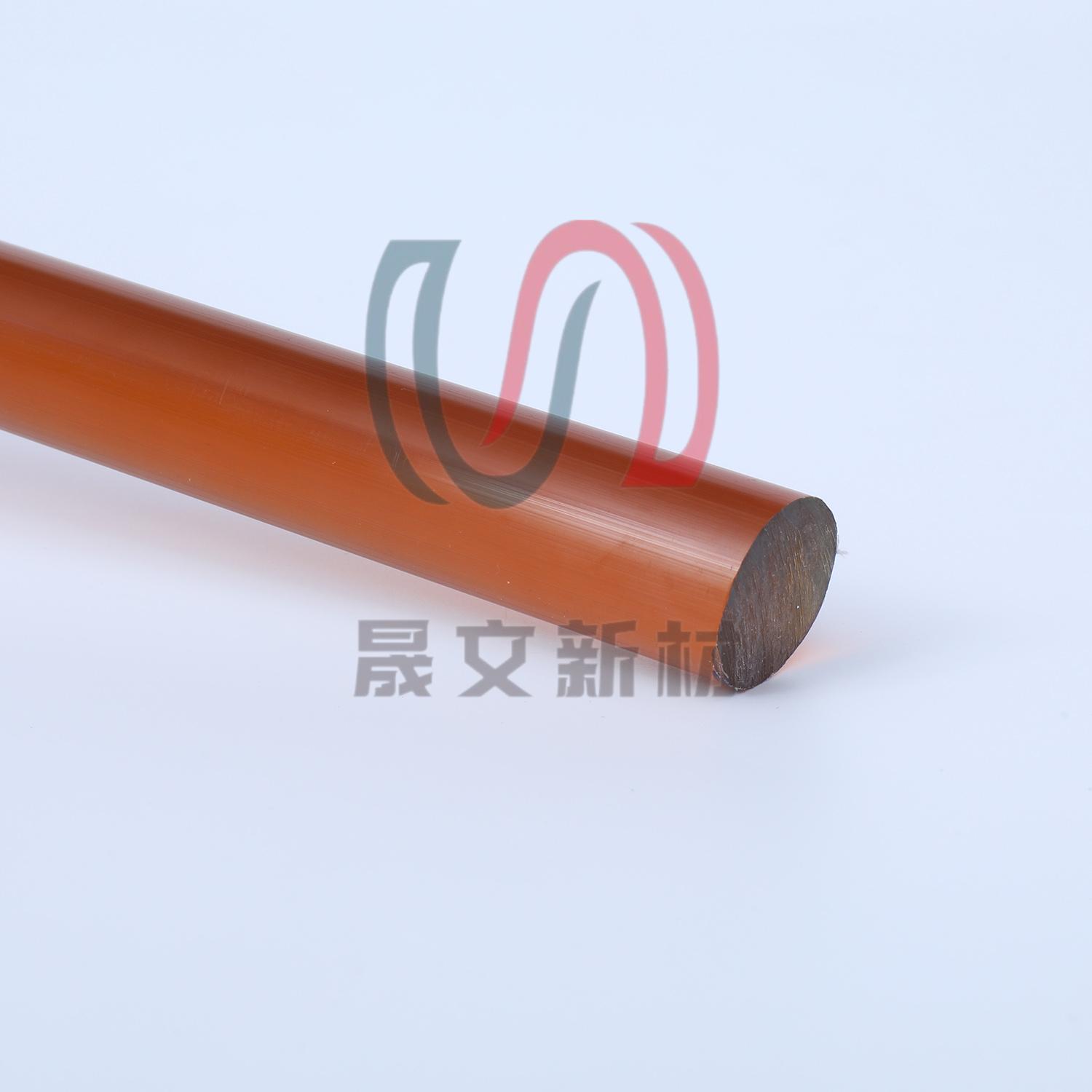

In this context, high-performance plastics or composite materials have become the new trend of replacing metal materials due to their advantages of light weight, corrosion resistance and high strength. Polyetherimide (PEI), as a class of high-performance engineering plastics, has shown great potential in the application of electrolyzer pole frame due to its unique performance.

The electrode frame is a key structural component of the electrolyzer and is mainly responsible for the following functions:

These functions pose comprehensive performance challenges for the material, including:

PEI (Polyetherimide) is an amorphous thermoplastic polymer with a combination of an aromatic imide backbone and an ether-bonded flexible structure. This molecular design confers excellent thermal stability, mechanical strength and chemical inertness.

Even under long-term high-temperature and high-humidity conditions, there is almost no significant degradation of its physical properties. Even under long term high temperature and high humidity conditions, there is almost no significant degradation of physical properties.

The imide ring in the molecular structure of PEI provides excellent chemical resistance to strong acids, bases, and oxidizing agents, and is particularly suitable for PEM and acidic hydrogen production environments. In the test, PEI materials can be stabilized in acidic media for more than 3000 hours, far more than other thermoplastics.

These properties ensure reliability and long life under high pressure sealing environments.

PEI has good electrical insulation properties and very low ionic contamination precipitation, which helps to prolong the life of the proton exchange membrane and avoid ionic migration contamination.

SABIC ULTEM™ PEI materials are extremely creep resistant, maintaining structural integrity and sealing under prolonged pressure loads, significantly reducing the risk of leakage. It is particularly well suited to the gas isolation sealing needs of PEM hydrogen production systems.

PEI has a water absorption rate of only about 0.7%, which minimizes dimensional changes under high temperature and high humidity conditions, avoiding structural deformation and sealing failures caused by water absorption and expansion.

PEI can realize complex geometric structure and thin-walled parts through injection molding process, which reduces metal processing, lowers the weight of parts, improves modular assembly efficiency, and is conducive to the miniaturization and standardization of hydrogen production equipment.

Compared with PPSU, PSU, PES and other materials, PEI shows higher modulus, stronger compression resistance and fatigue life, especially suitable for high-frequency operation, long cycle life requirements of hydrogen production electrolyzer system.

In actual PEM water electrolysis projects, bipolar plates made from PEI (such as ULTEM™ 1000/2300) have shown excellent sealing performance after 1000 cycles of high-temperature and humidity testing, with no structural damage or corrosion observed. Additionally, due to their low contamination characteristics, they significantly extend the lifespan of exchange membranes, reducing maintenance costs.

As the hydrogen industry accelerates, material upgrades for electrolyzers have become a critical factor affecting efficiency and reliability. PEI, with its superior comprehensive performance, is gradually replacing traditional metals and lower-performance plastics to become the preferred material for next-generation electrolyzer bipolar plates.

In the future, with continuous optimization of PEI processing technologies and application processes, the lightweight, high-efficiency, and long-life characteristics of electrolyzers will advance further, injecting new momentum into the development of green hydrogen.

Shengwen specializes in high-performance engineering plastic solutions, offering customized PEI-modified materials and injection-molded parts development services. Our PEI materials undergo rigorous screening and performance validation, widely used in advanced manufacturing sectors such as new energy, hydrogen, and semiconductors.

If you are developing electrolyzer projects or seeking alternative bipolar plate materials, feel free to contact us for samples and technical support!

By continuing to use the site you agree to our privacy policy Terms and Conditions.