As global interest in green hydrogen continues to surge, alkaline water electrolysis (AWE) remains a mainstream and cost-effective method for industrial-scale hydrogen production. In this system, the pole frame (also known as the electrolyzer frame or bipolar plate frame) plays a crucial structural and functional role. It supports the electrode plates, channels gas and liquid flows, and ensures electrical insulation and sealing under high-pressure alkaline conditions.

Traditionally, these frames are manufactured from carbon steel due to its strength and pressure resistance. However, with the increasing demands for durability, safety, and cost-efficiency, high-performance thermoplastics such as PPSU (Polyphenylsulfone) have emerged as a promising alternative.

In a typical AWE stack, each electrode unit consists of a main electrode plate and an outer pole frame. The pole frame is designed with multiple gas channels at the top and a set of liquid channels at the bottom to enable controlled injection and zoned circulation of the alkaline electrolyte.

Key functional zones of the pole frame include:

These structures must maintain precise geometries under prolonged exposure to highly corrosive, high-temperature, and high-pressure conditions, making the material selection critical.

Carbon steel has long been favored for its rigidity and pressure resistance. However, it presents several drawbacks when used in harsh alkaline environments:

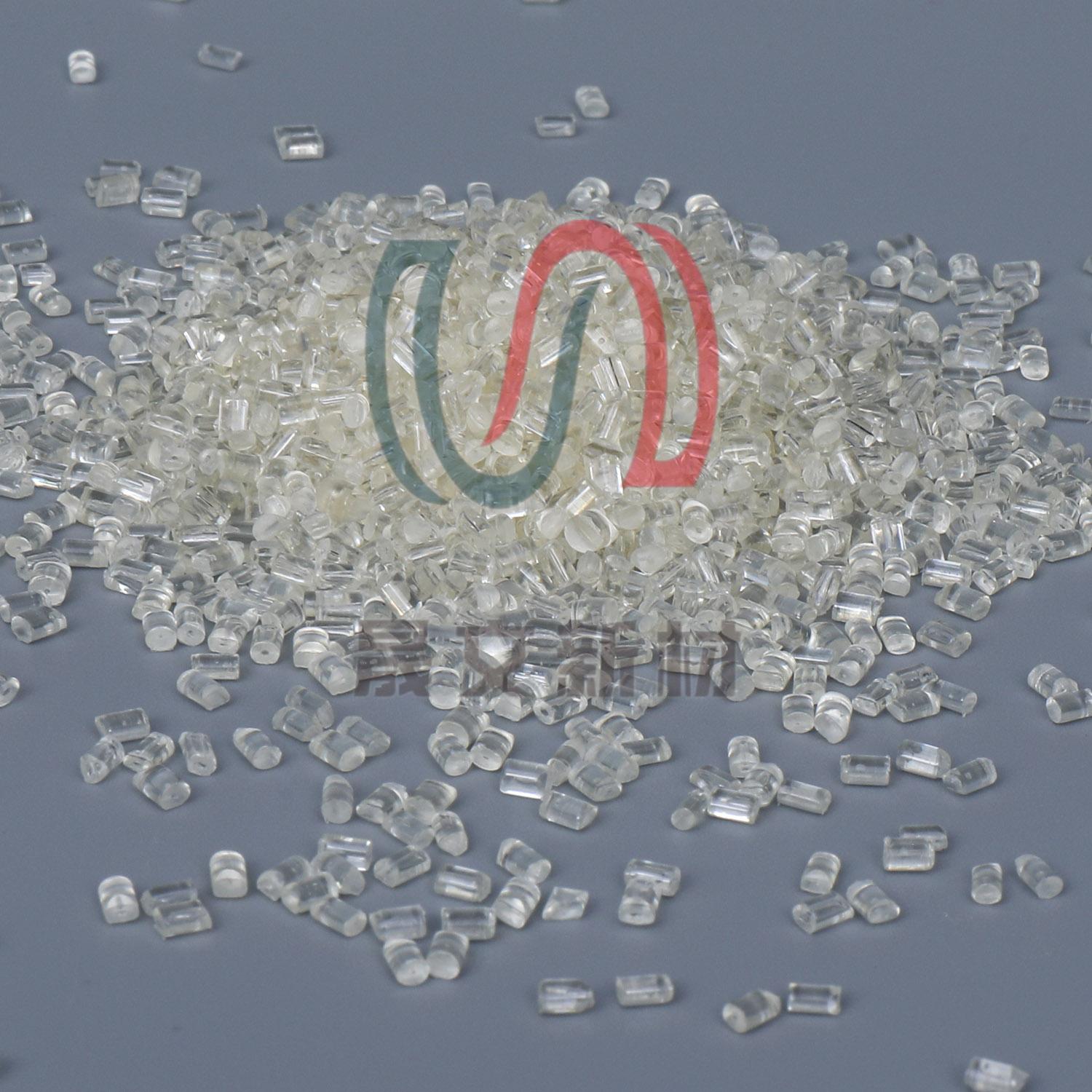

Polyphenylsulfone (PPSU), an amorphous, high-performance thermoplastic, offers a comprehensive solution to the challenges of metal frames. It excels in harsh chemical environments and delivers significant processing and functional advantages.

PPSU exhibits outstanding resistance to strong alkalis, acids, and oxidizing agents. In electrolytic environments with elevated KOH or NaOH concentrations, PPSU maintains structural integrity without swelling, cracking, or leaching, unlike conventional plastics or corroding metals.

With a heat deflection temperature (HDT/A) of 196 °C and relative temperature index (RTI) up to 180 °C, PPSU performs reliably in electrolysis systems that operate under elevated thermal loads.

PPSU offers a high tensile strength (~70 MPa) and excellent impact resistance (~690 J/m), allowing the frame to withstand electrolyte pressure, stack compression, and vibration without deformation or fracture.

As a naturally insulating polymer, PPSU reduces the risk of electric leakage or short circuits in modular stack designs—eliminating the need for secondary insulation treatments.

The lower density (~1.29 g/cm³) compared to metal dramatically reduces system weight. PPSU supports injection molding, enabling mass production of complex geometries (e.g., gas/liquid channels, tongue structures) with high dimensional precision and excellent repeatability.

In redesigned electrolyzer stacks using PPSU pole frames:

Shengwen New Materials is a trusted supplier of high-performance PPSU materials specifically formulated for high-temperature, chemical-resistant applications like electrolyzer pole frames.

Replacing traditional carbon steel with PPSU pole frames in hydrogen electrolyzers represents a strategic shift toward more durable, corrosion-resistant, lightweight, and cost-effective system designs. PPSU not only withstands harsh operating environments but also enables advanced component integration through precision molding.

By partnering with Shengwen New Materials, you gain access to reliable, engineering-grade PPSU backed by technical expertise and flexible customization—empowering your electrolyzer innovation for the hydrogen economy of the future.

By continuing to use the site you agree to our privacy policy Terms and Conditions.