PPSU

Overview :

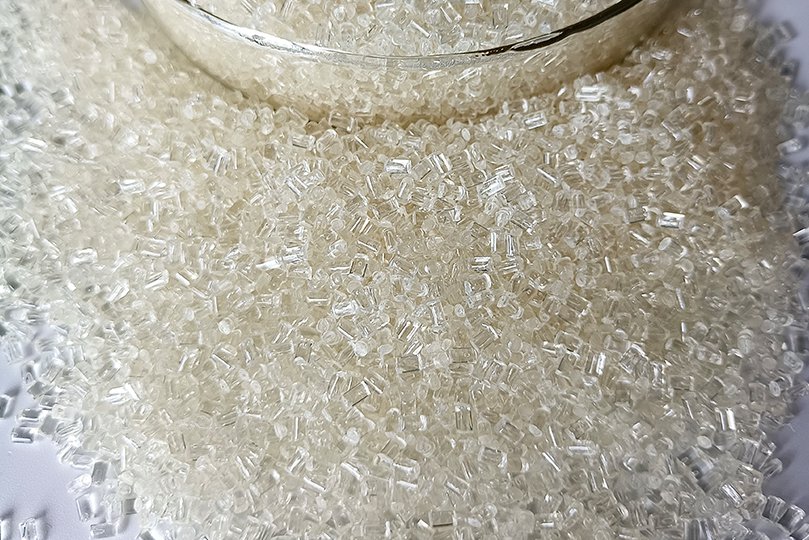

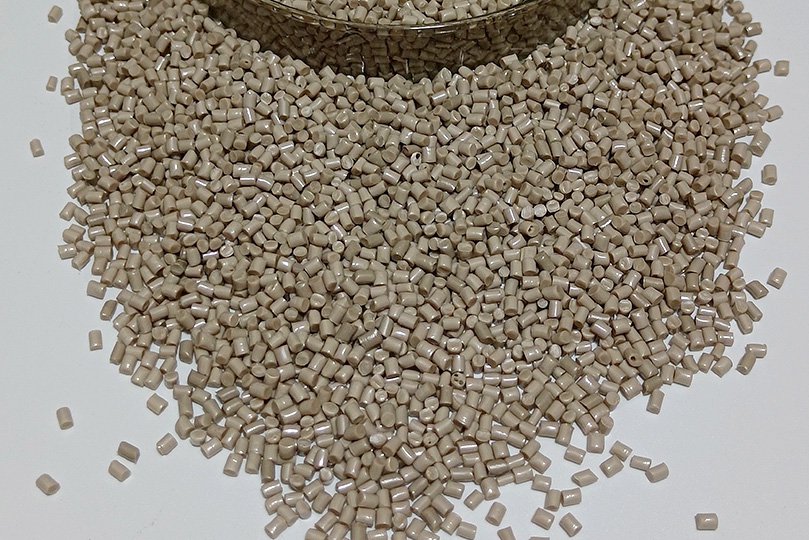

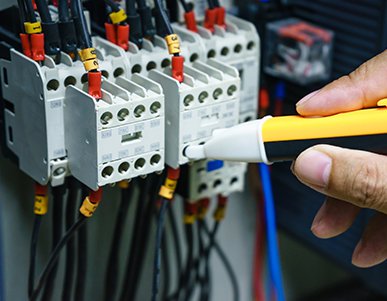

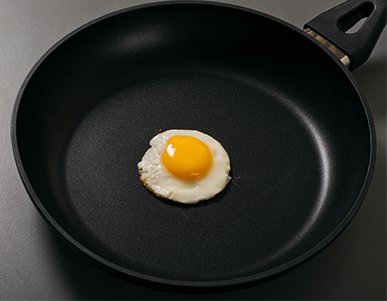

PES (polyethersulfone) is an amorphous polymer with excellent comprehensive properties. It combines good chemical resistance with a high heat deflection temperature of 205 °C(ISO 75). And PES resin is inherently flame retardant for application of electronic components and testing devices. Its chemical resistance and mechanical properties are better than PSU (polysulfone). Because of its good hydrophilic and lipophilic properties, PES can be used for non-stick pan coatings. PES has obtained ISO10993, NSF, EU10/2011, IATF16949, REACH and other certifications. As a high-performance material, PES is widely used in food containers, medical appliances, paints, non-stick coatings, insulating electrical and electronic parts, hemodialysis membranes, automotive fog lamps and many other fields.

The Main Specifications and Properties of PES

| Typical Value | Testing Method | Unit | F2050 | F2150 | F2250 | F2350 | F2550C Coating | F2150 GL20 | F2150 GL30 | ||

| MFR @ 380℃/2.16kg | ISO 1133 | g/10min | 5-15 | 15-25 | 25-35 | 35-45 | >45 | 10-20 | 10-20 | ||

| Density | ISO 1183 | g/cmᶟ | 1.37 | 1.37 | 1.37 | 1.37 | 1.37 | 1.5 | 1.5 | ||

| Moisture Absorption,Equilibrium 23℃/50% r.h | ISO 62 | % | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.6 | 0.6 | ||

| Mold shrinkage-Flow | ISO 2577, 294-4 | % | 0.82 | 0.82 | 0.82 | 0.82 | - | 0.36 | 0.36 | ||

| HDT/A @1.8MPa | ISO 75-1/-2 | ℃ | 205 | 205 | 205 | 205 | - | 220 | 220 | ||

| Tensile Strength | ISO 527-1/-2 | MPa | 88 | 88 | 88 | 88 | - | 125 | 125 | ||

| Tensile Modulus | ISO 527-1/-2 | MPa | 2700 | 2700 | 2700 | 2700 | - | 7300 | 7300 | ||

| Tensile Elongation(Yield) | ISO 527-1/-2 | % | 6.5 | 6.5 | 6.5 | 6.5 | - | 2.5 | 2.5 | ||

| Flexural Strength | ISO 178 | MPa | 120 | 120 | 120 | 120 | - | 150 | 150 | ||

| Flexural Modulus | ISO 178 | MPa | 2650 | 2650 | 2650 | 2650 | - | 6800 | 6800 | ||

| Notched Izod Impact | ISO 180/A | KJ/㎡ | 6.5 | 6.5 | 6.5 | 6.5 | - | 6.5 | 6.5 | ||

Typical Application

Polyethersulfone (PES) is a thermoplastic polymer material with a wide range of applications. It is known for its excellent mechanical strength, thermal stability, dimensional stability, and chemical resistance. Some common applications of PES include:

Auto Fog Lamp and Reflector Lighting

Electrical and Electronic Components

Coating, Cookware and Food Services

FAQ:

What plastic is PES?

PES plastic is a high temperature engineering thermoplastic with outstanding tolerance to temperatures for long periods. PES polymer offers high mechanical strength and rigidity, coupled with relatively low notch sensitivity. In addition, polyethersulfone offers good chemical compatibility and hydrolysis resistance.

Q1

What temperature does PES decompose?

Under air, the little shoulder and the two major peaks observed on the DTG curve of PES-OH (Fig. 4b) indicate that the polymer decomposes through a multi-step process completed around 650 °C.J

Q2

What are the properties of PES?

Important properties are: good mechanical behavior between −50 °C and 180 °C; high dimensional stability; transparency; and self-extinguishing.

Q3

Can you provide customized services?

Yes, all our raw materials can be customized, such as adding glass fiber, carbon fiber and other fillers, or making boards and rods of different sizes. Click for details to learn more>>

Can you provide the quality certificate of the products?

Of course. All of our products are proven to be perfectly compliant with FDA, REACH and RoHS safety regulatory, and so on. If you need, you can contact us to check the relevant documents.

Q5

Are you manufacturer or trading company?

We are integral part of industry and trade. Both the agency of some products, but also a factory for product development and production.

Q6

About bulk order leading time?

It will take about 15~30 working days from order confirmation to production completion. Specific communication can be coordinated to the time acceptable to both side.

Q7