PPSU

Overview :

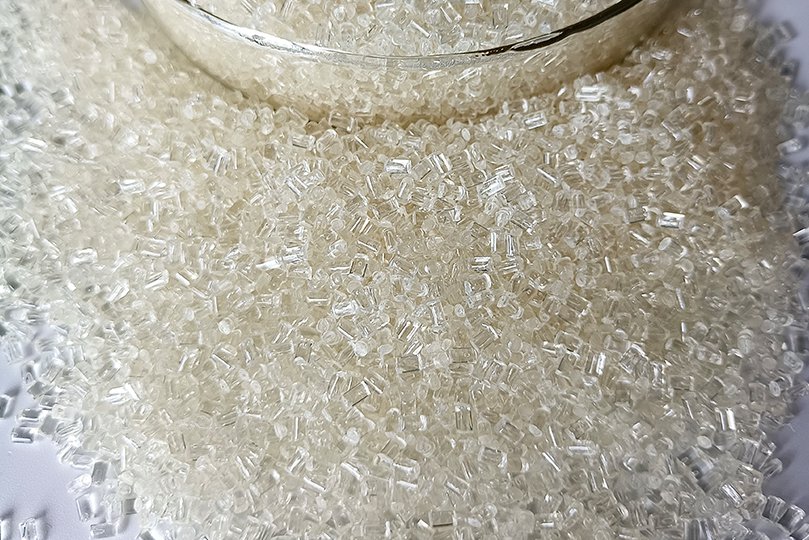

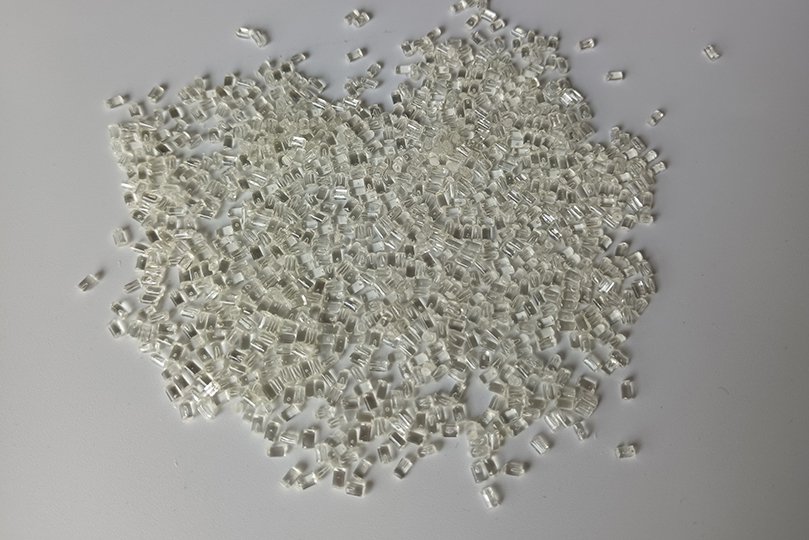

PSU (polysulfone) is an amber transparent plastic material with good mechanical properties such as good stiffness and strength, semi-toughness and high temperature. As a high-performance polysulfone polymer, its transparency is better than PPSU (polyphenylene sulfone) and PES (polyethersulfone). Compared with PC (polycarbonate), PSU can offer higher heat resistance and better hydrolytic stability. The material PSU has passed FDA, EU10/2011, NSF14/61, ACS, WRAS, W270, UL94, REACH, ROHS and other certifications. As a polysulfone material with excellent comprehensive properties, PSU can be used in water filtration membranes, water pipe joints, water dispenser parts, hemodialysis membranes, SF products and so on. Tuntun Plastic is a professional polysulfone manufacturer providing high quality psu material and psu rods at wholesale prices. Shop for PSU Rods & Sheets >>

Polysulfone Material Properties

-

Autoclave resistant

-

Excellent hydrolytic stability

-

High strength and rigidity

-

Excellent electrical properties

-

Good chemical resistance

-

Superior creep resistance

-

FDA, NSF, 3A-Dairy, and USP Class VI compliant

-

High temperature performance

-

Flame retardant

PSU Plastic Technical Specifications

Polysulfone is an amorphous high performance thermoplastic that offers excellent mechanical and electrical properties, as well as chemical resistance to acidic and salt solutions. These properties remain constant over a relatively broad temperature range (-150º F to 300º F). The melting point of Polysulfone (PSU) is approximately 232°C (450°F).

Polysulfone Applications

Polysulfone is used in several applications including:

- Medical devices: Polysulfone is used to manufacture dialysis membranes, fluid management devices, and other medical equipment.

- Aerospace: Polysulfone is used in fuel cells, air management systems, and other aerospace applications due to its high heat resistance and dimensional stability.

- Electronics: Polysulfone is used as an insulator in electronic devices due to its high electrical resistance and dimensional stability.

- Automotive: Polysulfone is used in automotive applications, such as fuel and brake lines, due to its high heat resistance and dimensional stability.

Animal Lab Cage

Membranes for Hemodialysis and Water Treatment

PSU Membranes

FAQ:

What is PSU material?

PSU (Polysulfone) is a type of thermoplastic polymer known for its high temperature resistance, chemical resistance, and toughness. It is often used in applications where stability under harsh conditions is important, such as medical devices, electrical components, and filtration systems.

Q1

Whether to provide the sample and the delivery time of the sample ?

We can provide a sample of 3kg in stock within 5 working days.

Q2

Can you provide customized services?

Yes, all our raw materials can be customized, such as adding glass fiber, carbon fiber and other fillers, or making boards and rods of different sizes. Click for details to learn more>>

Q3

What is the PSU (Polysulfone) color?

Polysulfone (PSU) is an amorphous thermoplastic that is typically transparent or slightly yellow in its natural state. However, it can be easily pigmented or tinted with a wide range of colors to meet specific design requirements. The color of PSU can vary depending on the specific pigments or additives used in the manufacturing process. Common colors of PSU include black, white, gray, blue, red, and green, among others.

Q4

Can you provide the quality certificate of the products?

Of course. All of our products are proven to be perfectly compliant with FDA, REACH and RoHS safety regulatory, and so on. If you need, you can contact us to check the relevant documents.

Q5

Are you manufacturer or trading company?

We are integral part of industry and trade. Both the agency of some products, but also a factory for product development and production.

Q6

About bulk order leading time?

It will take about 15~30 working days from order confirmation to production completion. Specific communication can be coordinated to the time acceptable to both side.

Q7

What is the chemical resistance of PSU?

PSU displays a very good chemical resistance to many chemicals including: aqueous systems, caustics, inorganic acids, aliphatic hydrocarbons, detergents and soaps and certain alcohols. This can be done by consulting the manufacturer's data sheets, conducting compatibility tests, or seeking advice from a technical expert.

Q8