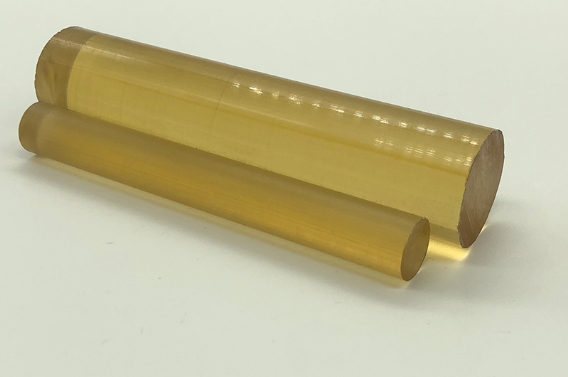

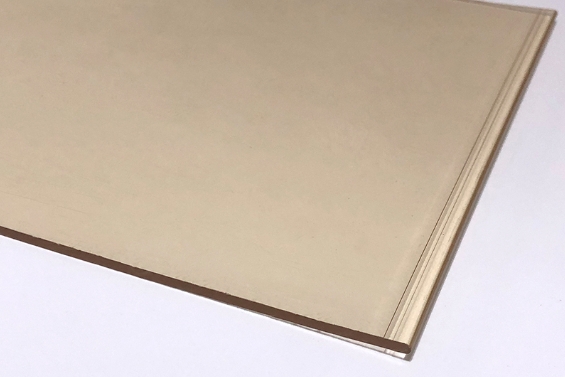

Polyphenylsulfone (PPSU) is a high-performance plastic material that offers several benefits when used for PPSU rods and boards in medical devices. In this article, we will explore why PPSU is gaining popularity in the medical industry and why it is considered the material of choice for medical device manufacturers.

PPSU has excellent chemical resistance, which makes it highly resistant to acidic or alkaline solutions, steam sterilization, and exposure to UV radiation. Medical devices require frequent cleaning and sterilization, which can lead to corrosion, discoloration, and degradation of other materials over time. PPSU’s superior chemical resistance ensures that medical devices retain their strength, durability, and performance even after repeated sterilizations.

PPSU is a biocompatible material that is approved by regulatory bodies such as the FDA and EU for use in medical devices. It is inert and does not react with human tissue, making it safe for long-term implantation. Additionally, PPSU does not have any adverse effects on blood or tissue samples, making it an ideal material for use in laboratory equipment.

Medical devices need to withstand impact and shock loads during transport, handling, and usage. PPSU has excellent impact resistance and can absorb energy without cracking, breaking, or deforming. This property helps in ensuring the safety and reliability of medical devices and reduces the risk of failure or injury.

PPSU has a high melting temperature (approximately 220°C) and can withstand high-temperature applications. This property makes it suitable for use in autoclaving and other high-temperature sterilization processes, without compromising its mechanical properties.

PPSU is a versatile material that can be easily molded, machined, and fabricated into complex shapes and sizes. This property allows medical device manufacturers to create customized designs that meet specific requirements and enhance the functionality of their products.

PPSU offers several advantages that make it an ideal material for rods and boards in medical devices. Its superior chemical resistance, biocompatibility, impact resistance, temperature resistance, and versatility make it a preferred choice for medical device manufacturers who prioritize quality, safety, and reliability in their products. With its unique combination of properties, PPSU is expected to play a significant role in the advancement of medical device technology in the future. If you are in need of PPSU rods and board, kindly contact us today.

By continuing to use the site you agree to our privacy policy Terms and Conditions.