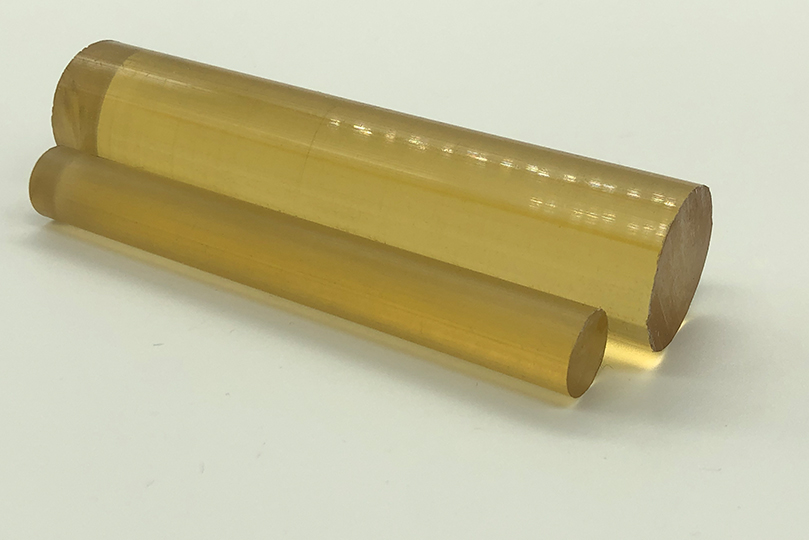

Are you looking for a high-performance material that can withstand harsh environments and extreme temperatures? Look no further than PPSU, or polyphenylsulfone. This thermoplastic is gaining popularity in various industries due to its exceptional properties, including toughness, chemical resistance, and hydrolytic stability. PPSU rods and boards are versatile and can be customized to fit specific application requirements, making them an excellent choice across numerous industries.

PPSU, or polyphenylsulfone, is a high-performance engineering thermoplastic that is becoming increasingly popular in various industries due to its unique properties. PPSU is characterized by its high strength, toughness, and resistance to high temperatures. It also has excellent chemical resistance and hydrolytic stability, making it ideal for use in harsh environments. PPSU can be manufactured in different forms such as rods and boards, depending on the application requirements.

PPSU is widely used in medical devices that require sterilization and high-temperature resistance. For instance, PPSU is used to make sterilization boxes, which help to ensure that medical instruments are free from bacteria and other harmful microorganisms. The ability of PPSU to withstand repeated sterilizations without losing its properties makes it an excellent choice for this application. Additionally, PPSU is also used to make handles of dental instruments, which need to be durable, lightweight, and easy to clean. Ventilator humidification tanks, which must be able to withstand exposure to moisture without degrading or losing their properties, are another example of PPSU's usefulness in the medical field.

PPSU’s ability to withstand hot water, steam, oil, or grease makes it an excellent candidate for food service applications. The material is biologically inert, BPA-free, and can withstand prolonged and repeated exposure to high temperatures without releasing any harmful chemicals. As a result, PPSU is commonly used for manufacturing food trays, which must be able to hold hot or cold foods without warping or melting. PPSU rods and boards are also used to make beverage dispensers, coffee machine parts, and other equipment that come into contact with food or beverages. These applications require a material with high strength and resistance to thermal stress, making PPSU the ideal choice.

PPSU is used in aircraft cabin interiors that require low heat release, low smoke generation, and low toxic gas emissions. Due to its exceptional toughness and impact strength, PPSU can withstand the harsh conditions of the aerospace environment while maintaining its mechanical properties. Furthermore, PPSU is resistant to cleaning agents and chemical disinfectants, which makes it an ideal material for manufacturing aircraft interior components. PPSU rods and boards can be molded-in color eliminating the need for painting, which helps to save time and costs during the manufacturing process.

PPSU's versatility makes it an excellent choice for a wide range of applications across multiple industries. Medical devices, food service equipment, and aircraft interiors are just some of the areas where PPSU rods and boards have made significant contributions. With its unique properties and adaptability, PPSU has become a reliable manufacturing material, offering numerous benefits and opportunities for innovation. The future looks bright for PPSU, and we can expect to see more advancements and applications of this remarkable material.

If you're interested in learning more about PPSU's versatility and how it can benefit your industry, contact us today to speak with one of our experts!

By continuing to use the site you agree to our privacy policy Terms and Conditions.