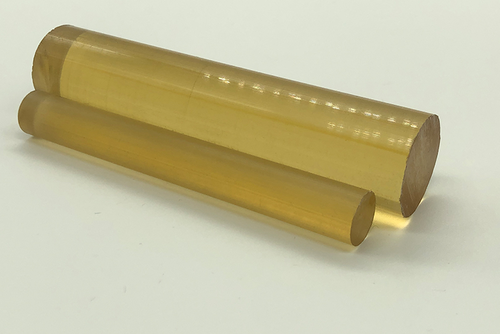

PPSU rods are known for their exceptional resilience and durability, making them an ideal choice for applications that demand high performance under extreme conditions. This article delves into the properties of PPSU rods that contribute to their robust performance and explores how they maintain integrity and functionality when faced with challenging environments.

One of the standout properties of PPSU rods is their remarkable thermal resistance. PPSU can withstand continuous exposure to temperatures up to 180°C (356°F) without compromising its mechanical properties. This makes PPSU rods suitable for use in applications such as aerospace and automotive industries, where components are regularly subjected to high temperatures.

PPSU rods exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and saline solutions. This chemical inertness ensures that PPSU rods can be used in harsh chemical environments without degrading. For instance, in the medical industry, PPSU rods are utilized for surgical instruments and devices that require frequent sterilization using aggressive chemicals. If you have any needs in this area, Shengwen's PPSU rods have medical grade reports that are perfect for the medical industry.

The impact strength of PPSU rods is superior to many other thermoplastics. This toughness makes PPSU rods an excellent choice for applications that experience high levels of mechanical stress or where impact resistance is critical. For example, PPSU rods are used in the manufacturing of parts for high-impact sports equipment.

PPSU rods also exhibit exceptional hydrolytic stability, meaning they maintain their physical properties even after prolonged exposure to hot water and steam. This characteristic is particularly beneficial for applications in the food and beverage industry and in medical devices that require autoclaving, a process that involves high-pressure steam sterilization. For example, the handles and wrenches used in surgery require long-term disinfection and sterilization, and PPSU rods with high hydrolysis resistance are ideal raw materials for manufacturing them.

Another significant advantage of PPSU rods is their resistance to gamma and electron beam radiation. This property is crucial for medical applications where sterilization through radiation is common. PPSU rods can undergo repeated radiation sterilization cycles without significant degradation, ensuring the longevity and reliability of medical instruments .

Given their exceptional properties, PPSU rods find applications across a wide range of industries facing extreme conditions:

PPSU rods stand out as a material of choice for demanding applications that require resistance to extreme temperatures, chemicals, impacts, and radiation. Their unparalleled performance in harsh conditions makes them indispensable in industries ranging from aerospace to medical, automotive, and food processing. As technology advances and the demand for materials that can withstand extreme environments grows, PPSU rods will continue to play a pivotal role in driving innovation and ensuring the reliability and safety of critical applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.