In the aerospace industry, material selection plays a pivotal role in ensuring performance, safety, and efficiency. Among the many high-performance polymers available, Polyetherimide (PEI) sheets have emerged as a preferred choice for both commercial aviation and space exploration applications.

This article examines the key properties that make PEI an ideal candidate for aerospace use and explores its diverse applications — from interior cabin components to structural parts in satellites and spacecraft.

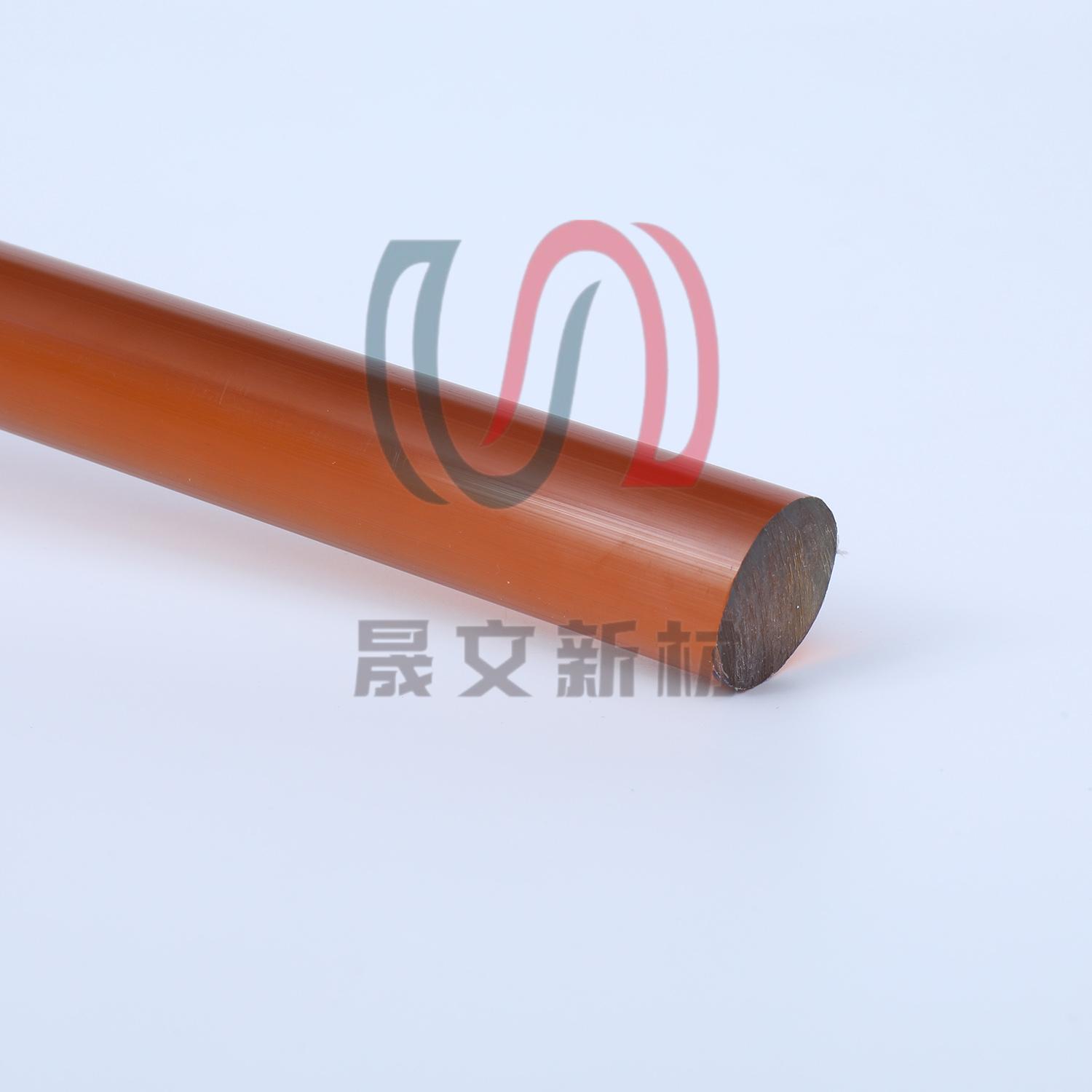

Polyetherimide, commonly referred to as PEI, is a semi-transparent, amorphous thermoplastic known for its excellent balance of mechanical strength, thermal resistance, and chemical stability. Unlike commodity plastics, PEI retains its physical properties even under prolonged exposure to elevated temperatures, making it suitable for environments where traditional materials may degrade or fail.

It is often supplied in sheet form, which allows for ease of fabrication through techniques such as thermoforming, machining, and bonding. Commercially recognized brands include ULTEM® and other proprietary formulations tailored for aerospace-grade performance.

The appeal of PEI lies in its ability to combine multiple desirable traits into a single material:

PEI maintains dimensional stability at continuous operating temperatures up to approximately 170°C, with short-term tolerance to even higher levels. This makes it suitable for applications involving heat exposure, such as near avionics or within engine compartments.

It offers high tensile strength and stiffness, along with good impact resistance. These characteristics ensure long-term reliability in structural and load-bearing applications.

Compared to metals and some other engineering polymers, PEI has a relatively low density (~1.27 g/cm³), contributing to weight reduction — a critical factor in aerospace design.

PEI exhibits inherent flame resistance and low smoke emission, meeting strict fire safety regulations required in aircraft interiors.

It shows strong resistance to common aerospace fluids such as hydraulic oils, jet fuel, and lubricants, enhancing component longevity

With good dielectric strength and stable electrical behavior across a wide temperature range, PEI is well-suited for electronic enclosures and insulating components.

Its thermoplastic nature allows for efficient manufacturing processes including CNC machining, vacuum forming, and adhesive assembly, facilitating complex geometries and streamlined production cycles.

Modern aircraft interiors demand materials that are not only functional but also visually appealing and easy to maintain. PEI sheets offer a unique combination of aesthetic flexibility and technical performance.

They are widely used in the fabrication of:

These components benefit from PEI’s ability to be formed into intricate shapes while maintaining durability and compliance with flammability standards.

Electronic systems are integral to modern aircraft operation, requiring protective housings that can withstand environmental stressors without compromising functionality. PEI provides an effective solution due to its mechanical rigidity, thermal resilience, and electrical insulation.

Common uses include:

These applications leverage PEI’s ability to protect sensitive electronics while remaining lightweight and flame-resistant.

Beyond Earth's atmosphere, materials must endure extreme conditions — from deep-space radiation to rapid thermal cycling between sunlight and shadow. PEI sheets formulated for aerospace use meet stringent outgassing requirements, ensuring they do not emit volatile compounds that could interfere with sensitive instruments.

Applications in the space domain include:

Its compatibility with clean-room processing and low particulate emissions further enhance its suitability for satellite and probe construction.

While PEI offers numerous advantages, it is important to consider potential limitations:

Despite these considerations, the overall performance profile of PEI continues to support its widespread adoption in aerospace sectors.

As aerospace technology advances toward more electric aircraft, reusable launch vehicles, and long-duration space missions, the need for high-performance, multifunctional materials will only grow.

Ongoing research aims to:

With continued innovation, PEI is expected to remain a vital material in the toolkit of aerospace engineers worldwide.

PEI sheets represent a class of advanced thermoplastics uniquely suited to the rigorous demands of aerospace engineering. Their combination of mechanical strength, thermal resistance, fire safety, and processability makes them ideal for a wide range of applications — from cabin interiors to mission-critical space systems.

As aerospace designers seek lighter, safer, and more durable materials, PEI will continue to play a central role in shaping the next generation of air and space vehicles.At Dongguan Shengwen New Materials Co., Ltd., we specialize in producing high-performance engineering plastics, including aerospace-grade PEI sheets and components. Our materials meet stringent industry standards for thermal stability, flame retardancy, and mechanical integrity, and are trusted across aerospace, electronics, medical, and industrial sectors. With professional support and customized solutions, Shengwen helps engineers and manufacturers meet the most demanding application requirements.

Contact us today to learn how our PEI solutions can enhance your aerospace innovations.

By continuing to use the site you agree to our privacy policy Terms and Conditions.