PEEK (Polyether Ether Ketone) is a high-performance thermoplastic material renowned for its exceptional mechanical, thermal, and chemical properties. Due to its versatility and reliability, PEEK is used across various industries including aerospace, automotive, medical, and manufacturing. In this article, we will explore the four main grades of PEEK, highlighting their unique characteristics and ideal applications.

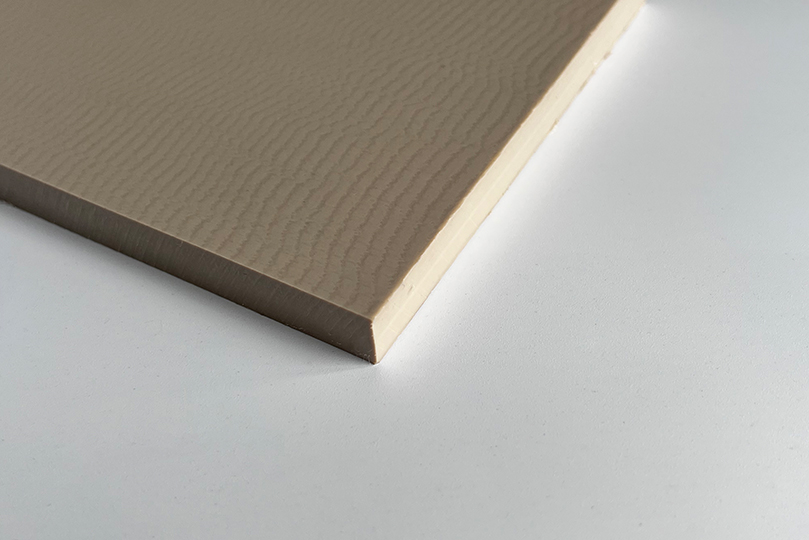

Unfilled PEEK is the most common and basic form of PEEK. It offers excellent mechanical properties, such as high strength and flexibility, making it suitable for a wide range of applications. This grade is known for its high elongation, toughness, and fatigue resistance.

Unfilled PEEK is ideal for applications in industries like medical, aerospace, and food processing, where purity and versatility are crucial. This grade complies with FDA regulations, ensuring it is safe for use in repetitive food contact and medical applications. Its excellent biocompatibility also makes it suitable for medical implants and devices.

While unfilled PEEK is pure and lacks reinforcements, it remains a preferred choice for many high-performance applications due to its balance of toughness, chemical resistance, and reliability. It is commonly available in colors like white, light brown, and black.

Glass-filled PEEK is reinforced with glass fibers, which enhances its strength, stiffness, and dimensional stability. The addition of glass fibers reduces the material's expansion, making it ideal for high-temperature applications where stability is critical.

This grade is commonly used in structural applications such as pump components, valve seats, and mechanical seals. The glass fibers increase the material's load-bearing capacity, making it perfect for heavy-duty applications in industries like automotive and manufacturing.

However, glass-filled PEEK can be more abrasive when in contact with other components, so it is essential to carefully evaluate its use in mating parts. Available in colors such as natural or black, this grade is popular in industries that require a balance of strength and stability.

Carbon-filled PEEK contains carbon fibers, which increase its stiffness, compressive strength, and wear resistance. This grade also offers excellent thermal conductivity, making it a superior choice for plastic bearings and other load-bearing applications.

The inclusion of carbon fibers enhances the material's thermal and electrical conductivity, which makes it ideal for use in aerospace, automotive, and industrial applications that require both high strength and heat resistance. Carbon-filled PEEK's enhanced wear resistance makes it suitable for components that endure continuous motion or contact, such as bearings and bushings.

This grade is typically black due to the carbon fibers and is best suited for high-stress applications where performance, wear resistance, and load-bearing capacity are critical.

Bearing-grade PEEK is designed specifically for use in bearing applications where low friction and high wear resistance are essential. It is often impregnated with PTFE (polytetrafluoroethylene) and graphite to improve its tribological properties, such as reducing the coefficient of friction and enhancing machinability.

This grade excels in applications like thrust washers, bushings, and other components where continuous motion and load-bearing capabilities are required. Bearing-grade PEEK is highly durable and resistant to wear, making it an ideal choice for industries like automotive, aerospace, and manufacturing.

The ability of bearing-grade PEEK to withstand high temperatures, reduce friction, and provide exceptional wear resistance makes it an indispensable material for heavy-duty, high-performance applications.

Each PEEK grade offers distinct advantages, and selecting the appropriate grade depends on the specific demands of the application. Whether you need a versatile material for medical devices, a stiff and strong material for structural components, or a highly wear-resistant option for bearings, there is a PEEK grade to meet your needs.

When deciding on the right PEEK grade, consider factors such as temperature resistance, wear resistance, chemical exposure, and mechanical strength. Each grade is tailored for specific applications, so understanding their properties can help you make the best choice for your industry.

At Shengwen, we provide a range of PEEK Rods & Boards designed to meet the highest industry standards. If you need assistance in selecting the right PEEK grade for your project, our team is here to provide expert advice and high-quality products tailored to your needs.

Contact us today to learn more about our PEEK materials and how we can support your business with innovative solutions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.