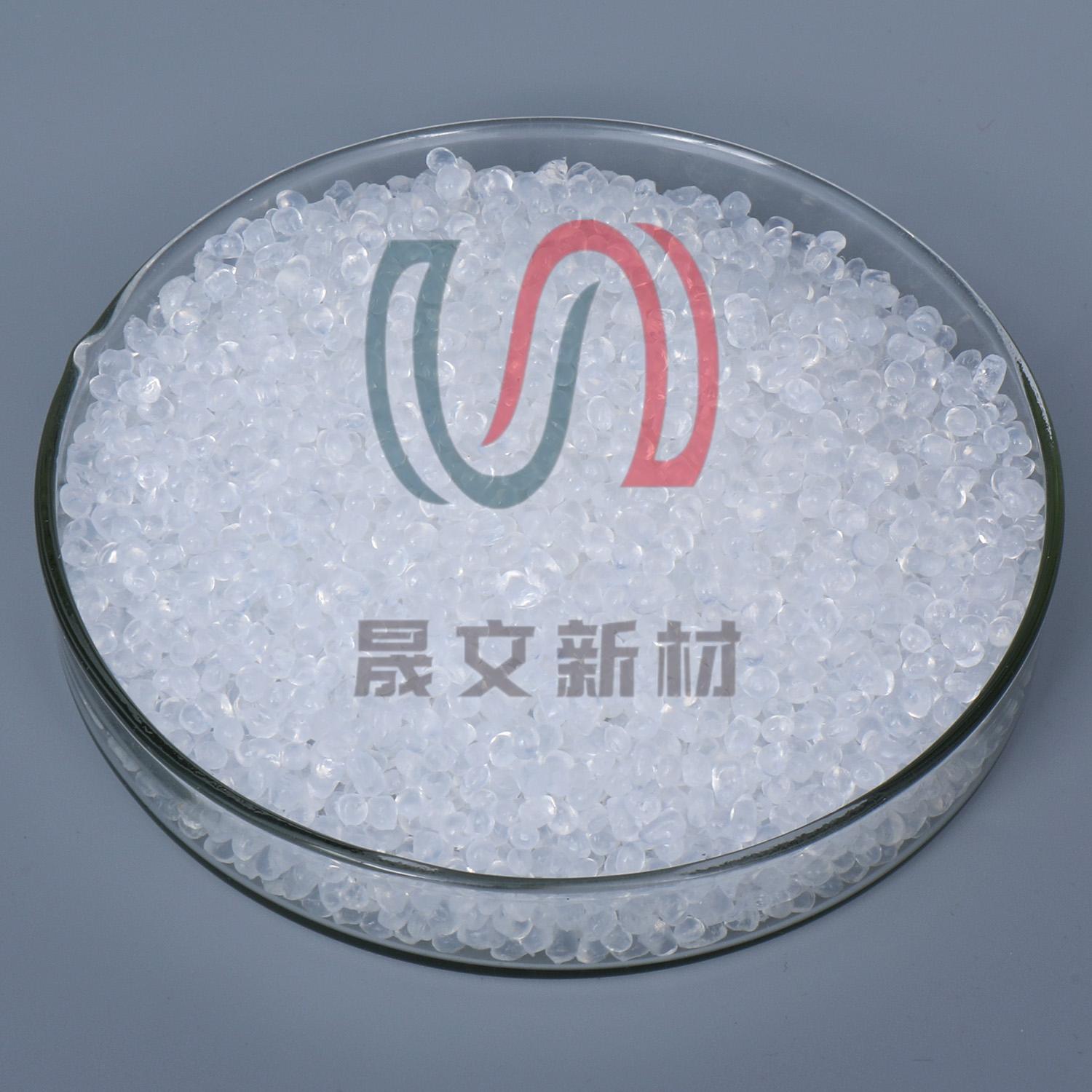

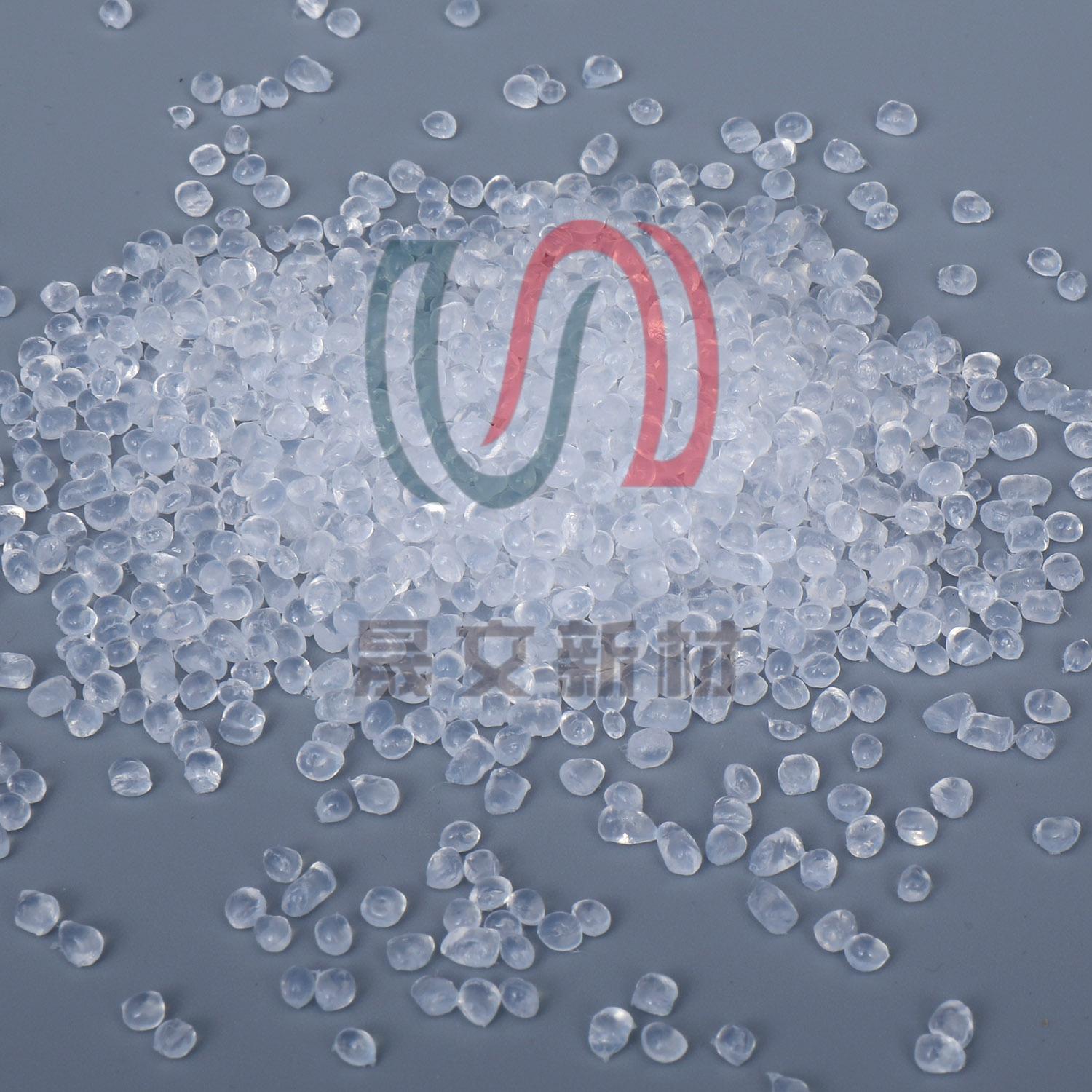

Polyamide 12 (PA12), commonly known as Nylon 12, belongs to the family of long-chain nylons. This classification refers to nylons whose molecular structure features an amide group with a chain of methylene groups (–CH2–) between the amide linkages that are longer than 10 carbon atoms. Examples of long-chain nylons include PA11 and PA12, with PA12 being one of the most widely used materials due to its exceptional properties.

Let’s explore why PA12 is regarded as a long-chain nylon and how its characteristics make it a standout material for various industrial applications.

Long-chain nylons, including PA12, exhibit a range of unique properties that distinguish them from traditional short-chain nylons (like PA6 or PA66). These advantages stem from their molecular structure and contribute to their superior performance in diverse applications.

One of the most notable features of PA12 is its low moisture absorption rate. While standard nylons (such as PA6) have a higher affinity for water due to their polar amide groups, long-chain nylons like PA12 have fewer amide groups, leading to significantly reduced moisture absorption. PA12, for example, absorbs only 0.6% of moisture, compared to 3% for PA6. This low moisture uptake ensures that PA12 retains its mechanical properties even in humid environments.

Because of its low moisture absorption, PA12 maintains exceptional dimensional stability. This characteristic is vital for producing high-precision components, especially in environments where humidity and temperature fluctuations are prevalent. PA12 components will not experience significant changes in size or performance, making them reliable for applications requiring consistent specifications over time.

PA12’s molecular structure, with its long carbon chain, allows for flexibility and high impact resistance. Even at low temperatures, PA12 retains excellent toughness, making it ideal for applications where both softness and resilience are needed. This property is particularly beneficial for creating parts that need to endure harsh conditions without cracking or losing their shape.

PA12’s combination of low moisture absorption, excellent toughness, and dimensional stability makes it a highly desirable material for a wide range of applications, particularly in the automotive and electrical industries.

In automotive manufacturing, PA12 is increasingly used in fuel lines, brake pipes, and other components that come into contact with oils, fuels, and other harsh chemicals. Its low moisture absorption ensures that parts maintain structural integrity even in wet or humid conditions. Additionally, PA12’s resistance to oil and fuel makes it the perfect choice for components exposed to these substances, where traditional materials might degrade over time.

PA12 is also a superior electrical insulator. Due to its low moisture absorption, PA12 retains its dielectric properties in humid conditions, unlike other nylons (such as PA6 and PA66) that may lose their insulating capacity. This makes PA12 a preferred material for electrical components like cables, connectors, and housings, ensuring reliable performance in both dry and wet environments.

PA12 excels in wear resistance, thanks to its low coefficient of friction and high resistance to abrasion. It is commonly used for parts that experience constant friction, such as bearings, bushings, and gears. PA12’s wear resistance ensures that these parts maintain high performance for longer periods, reducing maintenance costs and downtime.

The unique properties of PA12 make it suitable for a wide variety of industrial uses. Here are some of its most common applications:

PA12 is widely used in the automotive industry for fuel lines, brake lines, engine components, and other critical parts. Its ability to withstand high temperatures, chemicals, and mechanical stress makes it indispensable in creating reliable and long-lasting components.

As an excellent electrical insulator, PA12 is utilized in electrical systems, including wiring, connectors, and protective casings. Its durability and consistent performance in various environmental conditions make it a go-to choice for high-quality, long-lasting electronic components.

In addition to automotive and electronics, PA12 is used in consumer products like sports equipment, medical devices, and industrial machinery. Its flexibility, chemical stability, and ease of processing make it ideal for parts that require precision and durability.

PA12’s unique combination of low moisture absorption, excellent mechanical properties, and superior wear resistance makes it an outstanding choice for industries ranging from automotive to electronics and beyond. Whether you're designing parts for high-performance vehicles or ensuring reliable electrical insulation, PA12 is a material that delivers the best of both worlds—durability and flexibility.

As industries continue to prioritize high-performance materials, PA12 remains a reliable solution for demanding applications. If you are looking to incorporate PA12 into your next project or need more information on its benefits and applications, contact Shengwen today. Let us help you take your designs to the next level with this versatile, high-performance material.

By continuing to use the site you agree to our privacy policy Terms and Conditions.