In the realm of engineering plastics, PSU (Polysulfone) F3150 is a material that's gaining increasing recognition for its versatility and exceptional properties. In this comprehensive guide, we'll delve into the world of PSU F3150, exploring its characteristics, applications, and advantages. Whether you're a professional in the industry or just curious about the wonders of plastics, this article will provide you with valuable insights into the remarkable PSU F3150.

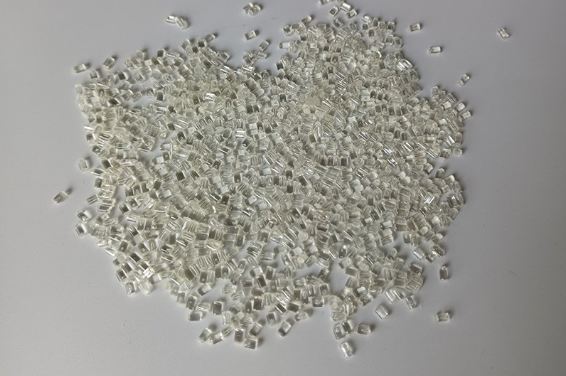

PSU, short for Polysulfone, is a high-performance thermoplastic known for its outstanding chemical resistance, heat resistance, and mechanical strength. PSU F3150 is a specific grade within the PSU family, prized for its unique combination of properties.

Exceptional Heat Resistance: PSU F3150 can withstand high temperatures, making it suitable for applications where exposure to heat is a concern.

Superior Chemical Resistance: This material is highly resistant to a wide range of chemicals, ensuring long-lasting durability in challenging environments.

Mechanical Strength: PSU F3150 boasts impressive mechanical properties, including high tensile strength and excellent impact resistance.

Transparency: One distinctive feature of PSU F3150 is its transparency, allowing for optical clarity in certain applications.

Due to its excellent sterilizability and resistance to harsh chemicals, PSU F3150 finds extensive use in medical devices and equipment. It is commonly employed in components like sterilization trays, medical tubing, and instrument handles.

In the aerospace industry, PSU F3150 is valued for its combination of heat resistance and lightweight properties. It is utilized in aircraft interior components, including cabin lighting covers and structural parts.

The material's excellent electrical insulating properties make it suitable for various electronic components, such as connectors, sockets, and insulators.

PSU F3150 is FDA-compliant and safe for use in food processing equipment. It is chosen for applications like hot water fittings, food containers, and ovenware.

In the automotive sector, PSU F3150's ability to withstand high temperatures and exposure to automotive fluids makes it suitable for under-the-hood components, including radiator tanks and pump housings.

1. Durability: PSU F3150 is designed to withstand harsh environments and maintain its mechanical properties over time, ensuring long-lasting performance.

2. Versatility: Its broad chemical resistance and temperature tolerance make PSU F3150 versatile for various industries and applications.

3. Transparency: The material's transparency is an advantage in applications where optical clarity is essential.

4. Compliance: PSU F3150 meets industry-specific regulatory requirements, such as FDA compliance for food-related applications.

5. Lightweight: Despite its strength, PSU F3150 is relatively lightweight, making it suitable for applications where weight is a consideration.

6. Customization: At Tuntunplastic, we offer customization services for PSU F3150, allowing you to tailor the resin's color, dimensions of boards or rods, and other performance aspects to meet your specific needs.

PSU F3150 stands as a remarkable engineering plastic with a wide range of applications and exceptional properties. Whether you're in the medical, aerospace, electronics, food processing, or automotive industry, PSU F3150 can provide the durability, versatility, and performance you need.

As a comprehensive company specializing in special engineering plastics, Tuntunplastic takes pride in offering high-quality materials like PSU F3150. With our annual output of 4,000 tons and customization services, we are committed to meeting your unique demands. Explore the power of PSU F3150 and discover how it can elevate your projects. Trust in Tuntunplastic for all your engineering plastic needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.