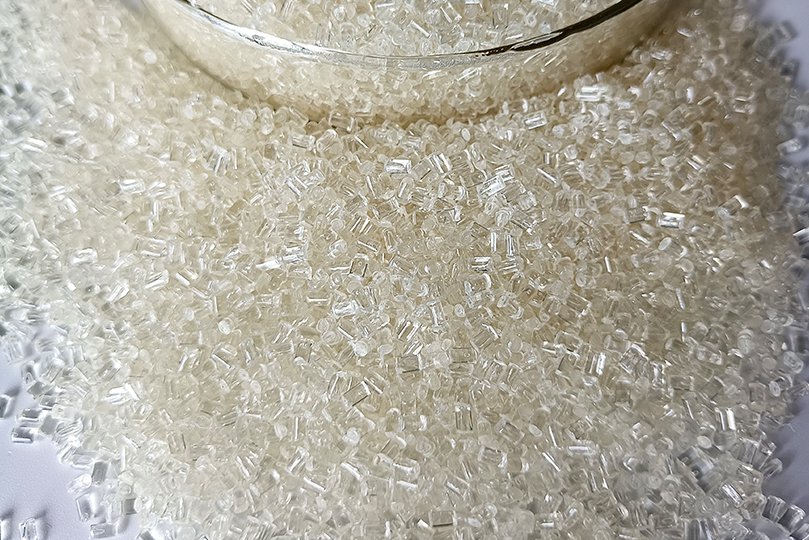

In the world of engineering plastics, making the right choice is paramount to the success of your project. Polysulfone (PSU) is a highly versatile engineering plastic, and PSU F3250 is one of its variants known for its unique properties and diverse applications. In this comprehensive guide, we'll walk you through the process of selecting the perfect engineering plastic by shedding light on the characteristics, advantages, and applications of PSU F3250.

Polysulfone (PSU) is celebrated for its excellent thermal stability and resistance to chemicals, but PSU F3250 takes these properties to a new level. Its remarkable features include:

PSU F3250 can withstand temperatures up to 325°F (163°C) without significant loss of properties, making it an excellent choice for applications in extreme thermal conditions.

It resists a wide range of chemicals, including acids, bases, and hydrocarbons, making it suitable for applications where exposure to corrosive substances is a concern.

PSU F3250 maintains its shape and mechanical properties even in hot and chemically aggressive environments, ensuring long-term reliability.

It boasts excellent electrical insulating properties, making it suitable for electrical and electronic applications.

The PSU F3250's exceptional durability and ability to withstand repeated sterilization make it a top choice for medical device components, including surgical instruments and fluid-handling systems.

The high-temperature resistance of PSU F3250 makes it ideal for aircraft interiors, including cabin components and lighting systems, ensuring safety and performance at elevated temperatures.

PSU F3250's electrical insulation properties are invaluable in electronic components, such as connectors, insulators, and circuit board housings.

It is used in various industrial applications, including valves, pump components, and heat exchangers, thanks to its resistance to chemicals and dimensional stability.

PSU F3250's FDA compliance makes it suitable for food contact applications, ensuring product safety and reliability.

Choosing PSU F3250 for your project involves careful consideration of several factors:

Evaluate whether your application involves high temperatures, and if so, PSU F3250's high-temperature resistance makes it a strong candidate.

If your project involves exposure to corrosive chemicals, PSU F3250's exceptional chemical resistance should be a primary consideration.

For electrical applications, its excellent electrical insulating properties are a clear advantage.

Determine if your project requires FDA compliance or other industry-specific certifications, where PSU F3250 excels.

In the world of engineering plastics, making the right choice can significantly impact the success of your project. PSU F3250, with its outstanding high-temperature resistance, chemical stability, and electrical insulation properties, offers a wide range of applications across industries. When it comes to selecting the right engineering plastic, choose reliability and versatility—choose PSU F3250.

For top-quality PSU F3250 and other engineering plastics, turn to Tuntun Plastic. With our commitment to excellence and innovation, we provide solutions that meet the most demanding engineering challenges. Contact us today to discover how we can elevate your projects with PSU F3250 and more.

By continuing to use the site you agree to our privacy policy Terms and Conditions.