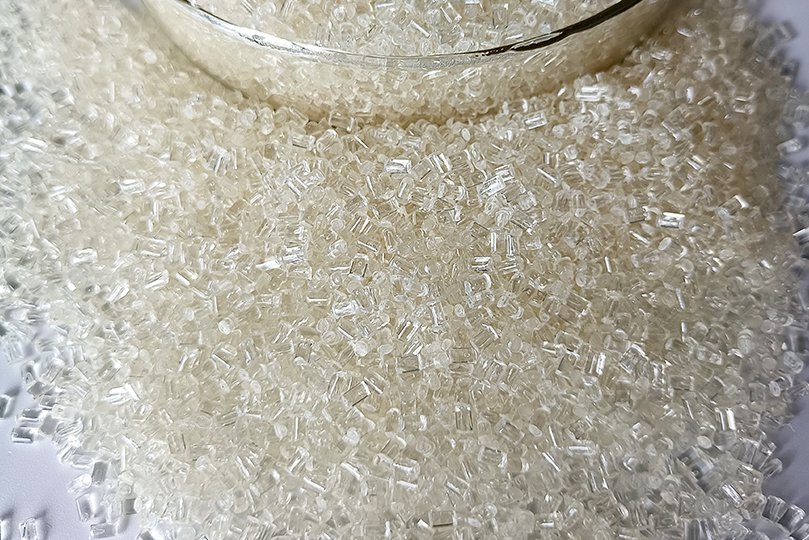

Sulfone polymers, including polysulfone (PSU), polyphenylsulfone (PPSU), and polyethersulfone (PES), are a class of high-performance thermoplastics renowned for their excellent mechanical properties, resistance to high temperatures, and broad chemical compatibility. These polymers are extensively used in industries like healthcare, aerospace, automotive, and electronics, owing to their versatility, durability, and superior performance in demanding environments. The ability to optimize these materials for specific end-use requirements is key to maximizing their effectiveness in various applications. This article explores how sulfone polymers can be tailored to meet the specific needs of different industries and use cases, with a special focus on the medical sector.

One of the first steps in optimizing sulfone polymers for a specific end-use is selecting the right grade based on the performance characteristics required. For example, in the medical device industry, both polysulfone and PPSU are commonly used due to their impressive resistance to hydrolysis, high-temperature stability, and biocompatibility.·

Polysulfone (PSU), with a heat deflection temperature (HDT) of 345°F (174°C), is often selected for applications that require high transparency, such as in medical housings and sterilization containers. Its ability to withstand repeated sterilization cycles makes it an ideal choice for equipment subjected to autoclaving processes.

Polyphenylsulfone (PPSU), which has an HDT of 405°F (207°C), offers enhanced performance in high-heat applications, including medical instruments that need to endure extensive autoclave cycles. PPSU is particularly suitable for long-term implantable devices due to its superior biocompatibility and chemical resistance.·

By choosing the appropriate sulfone polymer, manufacturers can ensure that the final product exhibits the necessary mechanical strength, thermal resistance, and biocompatibility required for its intended use.

Sulfone polymers' resistance to chemical attack and degradation from exposure to high-temperature water and steam is one of their strongest features. However, different sulfone grades can be optimized based on the specific environmental conditions they will face.

Hydrolytic Resistance: Polysulfone and PPSU are particularly resistant to hydrolysis, making them ideal for medical devices exposed to high-temperature water and steam, such as dialysis equipment and filtration membranes. Customizing the polymer formulation for improved resistance to water or steam can enhance the longevity and reliability of these devices.

Chemical Resistance: Polysulfone and PPSU also exhibit broad chemical resistance, but specific applications may require modifications to ensure they can withstand more aggressive chemicals. For instance, in the medical field, these polymers must resist degradation from bodily fluids or harsh sterilizing agents. By formulating sulfone polymers to meet specific chemical compatibility requirements, manufacturers can extend the service life and performance of their products.

One of the key benefits of sulfone polymers is their combination of rigidity, strength, and toughness. However, different applications may prioritize one of these properties over the others. To optimize sulfone polymers for a specific application, the balance of these characteristics can be adjusted.

By fine-tuning the formulation of sulfone polymers, manufacturers can create materials that meet specific mechanical performance standards, ensuring the end product performs as expected under real-world conditions.

In industries such as healthcare, biocompatibility is a critical consideration. Sulfone polymers like PSU and PPSU are known for their ability to meet regulatory standards for long-term biocompatibility. For medical devices, it’s essential that the material not only meets these standards but also performs consistently over time when in contact with bodily tissues or fluids.

Once the right sulfone polymer is selected, the next step is optimizing the processing methods to bring the design to life. Whether through injection molding, extrusion, or CNC machining, working with a specialized medical-grade plastics processor can significantly streamline this process.

Sulfone polymers, including polysulfone, polyphenylsulfone, and polyethersulfone, are indispensable materials across a variety of industries due to their high-performance characteristics. By carefully selecting the right polymer grade, optimizing for specific environmental conditions, balancing key mechanical properties, ensuring biocompatibility, and fine-tuning the processing methods, manufacturers can optimize sulfone polymers for a wide range of end-use applications.

If you're looking to optimize sulfone polymers for your next project, consider partnering with Shengwen. With our expertise in high-performance thermoplastics and advanced manufacturing capabilities, we can help you select and process the perfect material to meet your unique needs. Contact us today to learn more about our solutions and services tailored to your industry.

By continuing to use the site you agree to our privacy policy Terms and Conditions.