News

Site Editor

Site

/uploads/image/624e518adecd0.png

Selecting the right materials for high-temperature applications is crucial, especially in industries like aerospace, automotive, medical, and electronics.

Site

/uploads/image/624e518adecd0.png

Selecting the right materials for high-temperature applications is crucial, especially in industries like aerospace, automotive, medical, and electronics.

How to Choose Special Engineering Plastics for High-Temperature Environments

Views: 2027

Author: Site Editor

Publish Time: 2024-10-25

Origin: Site

Selecting the right materials for high-temperature applications is crucial, especially in industries like aerospace, automotive, medical, and electronics. Special engineering plastics offer excellent thermal stability, mechanical strength, and chemical resistance, making them indispensable in such demanding environments. However, choosing the right plastic depends on the specific requirements of the application, including temperature resistance, mechanical properties, and environmental factors.

Key Factors to Consider

When working with high-temperature environments, it's essential to carefully evaluate several key aspects to ensure the chosen plastic meets all performance requirements. Below are the main factors to consider:

-

Thermal Stability The primary consideration for high-temperature environments is the material's ability to maintain its structural integrity at elevated temperatures. Special engineering plastics are designed to withstand high thermal loads without significant degradation. When selecting a material, it's essential to know its glass transition temperature (Tg) and melting point (Tm) to ensure that it will not soften or deform under the operating conditions.

-

Mechanical Properties High-temperature environments can place considerable stress on materials, particularly in dynamic applications. The chosen plastic must retain its tensile strength, impact resistance, and dimensional stability even when exposed to elevated temperatures for prolonged periods. Some plastics lose strength or become brittle when heated, so selecting a material that maintains its toughness is crucial.

-

Chemical Resistance Many high-temperature applications involve exposure to harsh chemicals or corrosive environments. Engineering plastics used in these applications must resist degradation from chemicals, solvents, or fuels. Materials like polyetheretherketone (PEEK) and polyphenylsulfone (PPSU) excel in both high-temperature and chemically aggressive conditions.

-

Wear and Friction In mechanical applications like bearings, gears, or seals, high temperatures can exacerbate wear and increase friction between components. Plastics with excellent wear resistance and low friction coefficients are ideal for such applications, reducing the need for lubrication and extending component lifetimes. Some plastics can also be enhanced with additives like PTFE to improve their performance in frictional environments.

-

Dimensional Stability Changes in temperature often cause plastics to expand or contract. In applications where precision and tight tolerances are critical, such as in electronics or aerospace, materials must offer low thermal expansion to maintain dimensional stability. Engineering plastics with minimal thermal expansion prevent warping and maintain the integrity of the system even in fluctuating temperatures.

-

Electrical Properties Many high-temperature environments involve electronic components, and the plastic material must not only withstand heat but also offer excellent electrical insulation or, in some cases, controlled conductive properties. Polyetherimide (PEI), for example, is commonly used in electronic components due to its high dielectric strength and thermal resistance.

Top Special Engineering Plastics for High-Temperature Applications

Having a clear understanding of the key factors is essential, but knowing which plastics meet these criteria can further simplify the selection process. Below are some of the top engineering plastics known for their high-temperature performance:

-

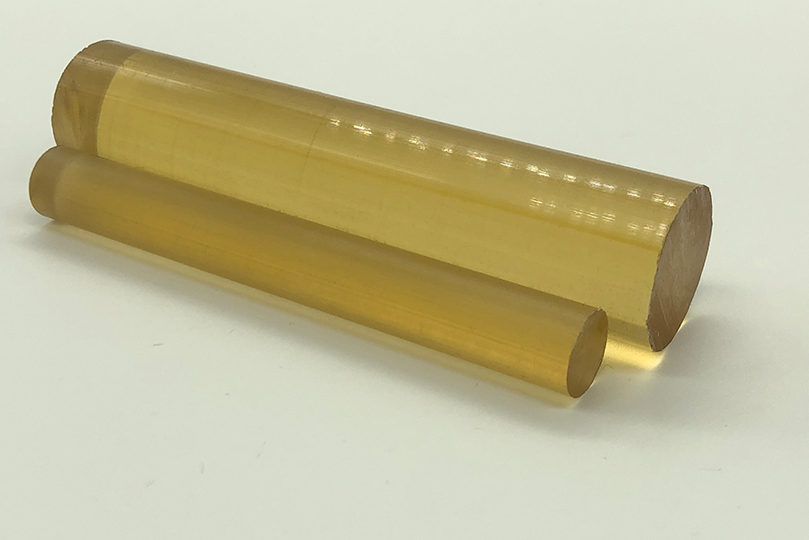

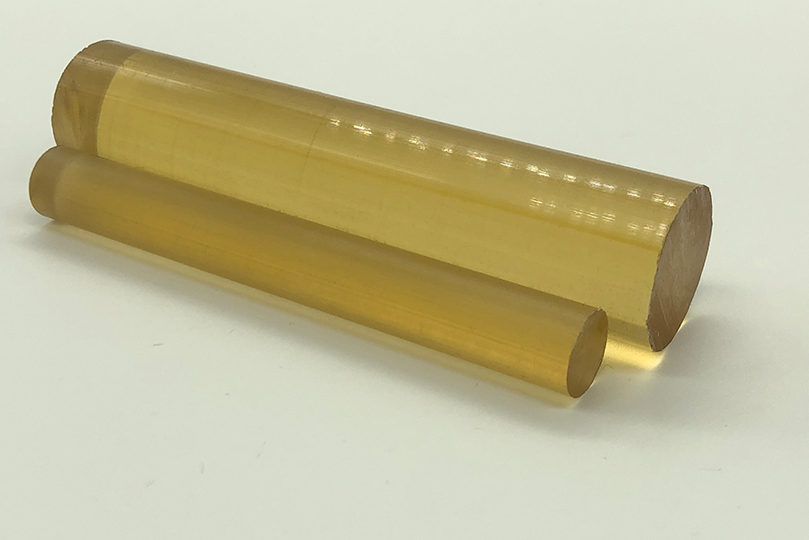

Polyetheretherketone (PEEK) PEEK is one of the most versatile and high-performing engineering plastics available, with excellent thermal, chemical, and mechanical properties. It can withstand continuous use at temperatures up to 260°C and maintains its strength even in chemically aggressive environments. PEEK is often used in aerospace, automotive, and oil and gas industries for components like bearings, valves, and seals.

-

Polysulfone (PSU) PSU offers high mechanical strength and is resistant to both heat and chemicals. It performs well at temperatures up to 160°C and is widely used in medical devices, plumbing, and food processing equipment. Its biocompatibility and resistance to sterilization processes make it ideal for applications requiring frequent cleaning.

-

Polyimide (PI) Known for its exceptional heat resistance, polyimide can withstand continuous use at temperatures exceeding 300°C. It also offers excellent chemical resistance and is often used in aerospace, electronics, and automotive industries for insulation, seals, and films.

-

Polyphenylsulfone (PPSU) PPSU is another strong contender for high-temperature environments, offering thermal stability up to 180°C. It also resists hydrolysis, making it ideal for hot water systems, medical applications, and food processing equipment. Its toughness and impact resistance further enhance its suitability for high-performance applications.

-

Polyetherimide (PEI) PEI, like PEEK, is a high-performance plastic that maintains its properties at temperatures up to 170°C. It offers excellent dimensional stability, making it suitable for precision components in electronics, automotive, and medical applications.

Conclusion

When choosing special engineering plastics for high-temperature environments, it’s essential to evaluate not only thermal resistance but also other factors like mechanical strength, chemical resistance, wear properties, and dimensional stability. The right material will ensure long-term reliability, reduce maintenance costs, and improve overall system performance. By carefully considering these factors, industries can select the ideal engineering plastic for their specific high-temperature applications.

Dongguan Shengwen Plastic Trading Co., Ltd. is a leading supplier of specialized engineering plastics, offering materials such as RodneyⓇ transparent nylon PA12, KygerⓇ polyamide elastomer, and advanced high-temperature plastics like PSU, PEI, and PEEK. With a dedicated team of engineers and state-of-the-art production facilities, Shengwen provides tailored solutions to meet the demands of industries including medical, automotive, aerospace, and electronics. All materials comply with international certifications, ensuring quality and safety in every application.