A water treatment membrane is a material with a selective separation function. The process of separating, purifying and concentrating different components of sewage by the selective separation of water treatment membranes is called membrane separation. It differs from traditional filtration in that water treatment membranes can be separated in the molecular range, and this process is a physical process without phase change and the addition of additives.

Those who have been in the industry for a few years will remember the once ubiquitous cellulose triacetate (CTA) membrane. A popular material in the mid-1990s was thin film composites (TFCs), which reduced the total cost of ownership and increased flux at lower driving pressures. Composite membranes can be made from a variety of materials such as polyethersulfone (PES), polysulfone (PSU), polyphenylsulfone (PPSU), polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF) and even polypropylene (PP). Today, the vast majority of devices use composite membranes.

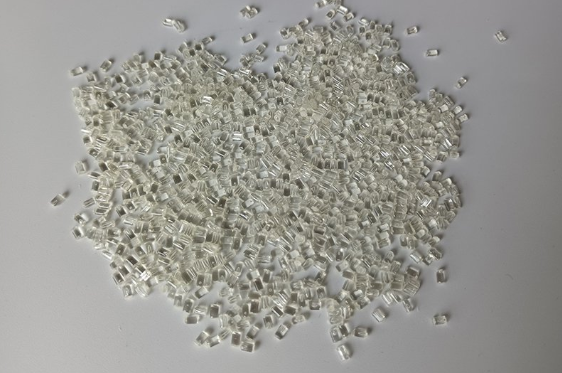

PSU is a high-rigidity, high-strength, transparent plastic that retains its original mechanical properties well when exposed to steam or other sterilization environments. It has many advantages such as excellent chemical resistance, hydrolysis stability and excellent film-forming properties.

High-viscosity PSU is an ideal material for the production of water treatment membranes. Higher molecular weight can improve fiber strength and reduce fiber damage. This improves the stability of the casting solution, avoids filter clogging in the production line and minimizes defects in the manufacturing process.

The pore size of water treatment membranes is generally microns. According to the different pore sizes, water treatment membranes can be divided into microfiltration membranes, ultrafiltration membranes, nanofiltration membranes and reverse osmosis membranes. According to different materials, it can be divided into inorganic membranes and organic membranes. Inorganic membranes are mainly microfiltration-grade membranes, ceramic membranes and metal membranes. Organic membranes are made of polymer materials, such as cellulose acetate, aromatic polyamide, polyethersulfone, and polyfluoropolymer.

Tuntunplastic is a comprehensive company specializing in the production, sales and service of special engineering plastic, including PPSU, PSU, PES, PA12, PEEK, PEBA, which are used in many fields. The PSU material of the water treatment membranes sold by our company has relevant certificates. If you are interested in it, please contact us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.