News

Site Editor

Site

/uploads/image/624e518adecd0.png

Polyetherimide (PEI) is one of the most versatile and high-performance engineering plastics available today.

Site

/uploads/image/624e518adecd0.png

Polyetherimide (PEI) is one of the most versatile and high-performance engineering plastics available today.

Everything You Need to Know About PEI Rods and Boards: Strength, Durability, and More

Views: 2941

Author: Site Editor

Publish Time: 2024-09-18

Origin: Site

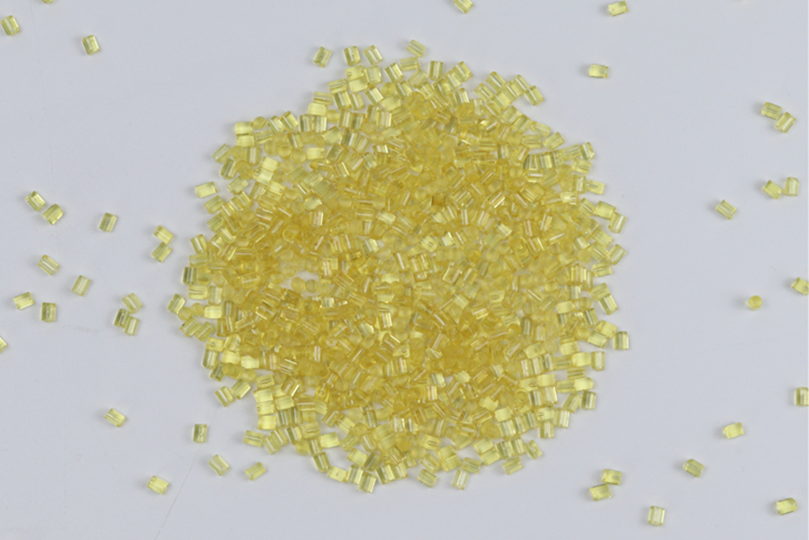

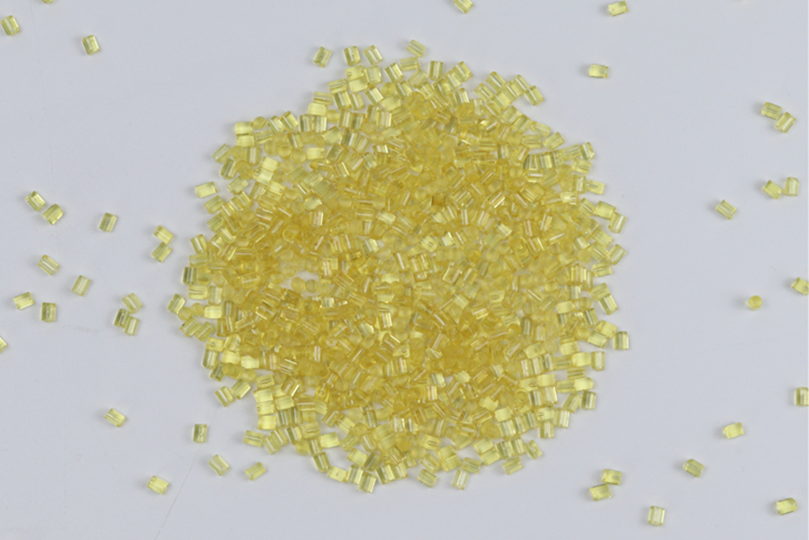

Polyetherimide (PEI) is one of the most versatile and high-performance engineering plastics available today. Known for its exceptional mechanical strength, thermal stability, and chemical resistance, PEI has become a go-to material for various demanding applications.This article will delve into the features of PEI rods and boards, highlighting their strength, durability, and other critical properties that make them indispensable in modern manufacturing.

What is PEI?

Polyetherimide (PEI) is an amber-colored, amorphous thermoplastic that belongs to the family of high-performance polymers. It is commonly recognized by its commercial name, ULTEM™, and is highly regarded for its superior thermal and mechanical properties. PEI is used across industries that demand materials with excellent performance under extreme conditions, such as aerospace, automotive, medical, and electronics.

Key Features of PEI Rods and Boards

PEI rods and boards offer an array of beneficial properties that make them suitable for various high-performance applications. Below are some of their key features:

-

Outstanding Mechanical Strength

PEI exhibits excellent tensile and flexural strength, making its rods and boards ideal for applications requiring high mechanical performance. The material maintains its strength even at elevated temperatures, ensuring reliability under stress and load-bearing conditions.

-

High-Temperature Stability

One of the standout characteristics of PEI is its ability to maintain mechanical and dimensional stability at high temperatures. PEI rods and boards can withstand continuous use in environments with temperatures up to 170°C, and even higher in short bursts. This makes them suitable for use in heat-intensive applications such as engine components or high-performance electronics.

-

Excellent Dimensional Stability

PEI exhibits low thermal expansion, ensuring that it maintains its shape and size even when exposed to significant temperature fluctuations. This property is crucial for precision parts and components where tight tolerances are required, especially in industries like aerospace and automotive

-

Superior Chemical Resistance

PEI offers excellent resistance to a wide variety of chemicals, including hydrocarbons, alcohols, and weak acids. This chemical resistance makes PEI rods and boards well-suited for use in harsh environments where exposure to aggressive substances is common.

-

Flame Retardant

PEI is inherently flame-retardant without the need for additional additives, and it exhibits low smoke generation when exposed to fire. This characteristic is vital for applications in the aerospace, transportation, and electrical industries, where fire safety is a priority.

-

Good Electrical Insulation

PEI has excellent dielectric properties, providing high electrical insulation. This makes PEI rods and boards a preferred material for electrical and electronic components, where insulation and stability under heat are required.

-

Easy Machinability

PEI rods and boards are relatively easy to machine into complex shapes and precision parts using standard machining techniques. Their machinability makes them a popular choice for custom components in a wide range of industrial applications.

Strength and Durability of PEI Rods and Boards

PEI rods and boards are renowned for their strength and durability, making them suitable for demanding applications where lesser materials may fail. Below are a few of the most notable aspects of their strength and durability:

-

Impact Resistance: PEI rods and boards offer good impact resistance, allowing them to absorb mechanical shocks and resist cracking. This makes them a preferred choice for applications requiring both rigidity and toughness.

-

Creep Resistance: PEI provides excellent resistance to deformation under continuous load (creep). This ensures long-term performance and reliability, especially in mechanical components subjected to constant stress or pressure.

-

Fatigue Resistance: PEI's resilience allows it to withstand repeated cycles of mechanical stress, making it an excellent material for moving parts and components that experience vibration or fluctuating loads.

-

UV and Radiation Resistance: PEI is naturally resistant to UV light and gamma radiation, which helps maintain its mechanical properties and appearance over time. This makes it suitable for use in outdoor applications and environments exposed to radiation, such as medical equipment.

Applications of PEI Rods and Boards

The combination of mechanical strength, thermal stability, and chemical resistance makes PEI rods and boards useful across a wide range of industries. Some key application areas include:

-

Aerospace

PEI is used in aircraft interior components, structural parts, and electrical insulators due to its flame-retardant properties, dimensional stability, and durability at high altitudes and varying temperatures.

-

Automotive

In the automotive industry, PEI is used for parts such as lighting reflectors, sensor housings, and electrical connectors, where high-temperature performance and mechanical strength are essential.

-

Medical Devices

PEI rods and boards are commonly used in the medical sector for sterilizable devices, such as surgical instruments and dental equipment, due to their resistance to heat, chemicals, and radiation.

-

Electronics and Electrical Engineering

PEI’s electrical insulation properties make it a favored material for circuit boards, connectors, and insulators in high-performance electronic devices.

-

Industrial Machinery

PEI rods and boards are often used in industrial machinery components that require high precision and resistance to wear, heat, and chemicals, such as bearings, gears, and bushings.

Limitations of PEI

While PEI offers numerous advantages, it also comes with certain limitations that need to be considered before selecting it for an application:

-

Higher Cost

As a high-performance engineering plastic, PEI is more expensive compared to other common thermoplastics. The higher cost can be a factor when selecting materials for large-scale projects or cost-sensitive applications.

-

Brittleness at Low Temperatures

Although PEI performs well at elevated temperatures, it can become brittle in very low-temperature environments, which may limit its use in certain applications requiring flexibility in cold climates.

-

Limited Availability in Custom Colors

PEI is naturally amber-colored, and while it can be pigmented, the range of available custom colors may be limited compared to other plastics.

Conclusion

Polyetherimide (PEI) rods and boards offer an impressive range of properties, making them an essential material in industries that require strength, durability, and resistance to heat and chemicals. While the material may have some limitations, the combination of its mechanical, thermal, and electrical properties makes it an excellent choice for high-performance applications across multiple sectors.

At Dongguan Shengwen Plastic Trading Co., Ltd., we are committed to providing top-quality PEI rods and boards to meet your specific project needs. Contact us today to learn more about how PEI can enhance the performance of your applications and help drive your business forward.

At Shengwen, we provide high-quality PEI rods and boards to meet diverse industrial needs.