News

Site Editor

Site

/uploads/image/624e518adecd0.png

In today’s world, the demand for clean and safe drinking water is growing at an unprecedented rate.

Site

/uploads/image/624e518adecd0.png

In today’s world, the demand for clean and safe drinking water is growing at an unprecedented rate.

Why PSU is Ideal for High-Performance Water Filtration Membranes

Views: 1893

Author: Site Editor

Publish Time: 2024-09-23

Origin: Site

In today’s world, the demand for clean and safe drinking water is growing at an unprecedented rate. As water filtration technologies advance, the materials used in creating high-performance membranes are crucial to ensuring filtration efficiency, durability, and safety. Polysulfone (PSU) has emerged as one of the leading materials for manufacturing water filtration membranes due to its excellent properties. This article explores why PSU is the ideal choice for high-performance water filtration membranes.

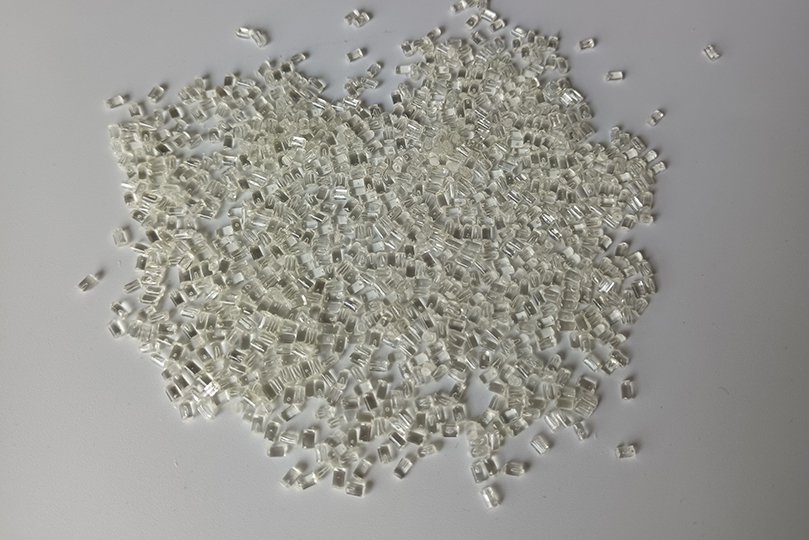

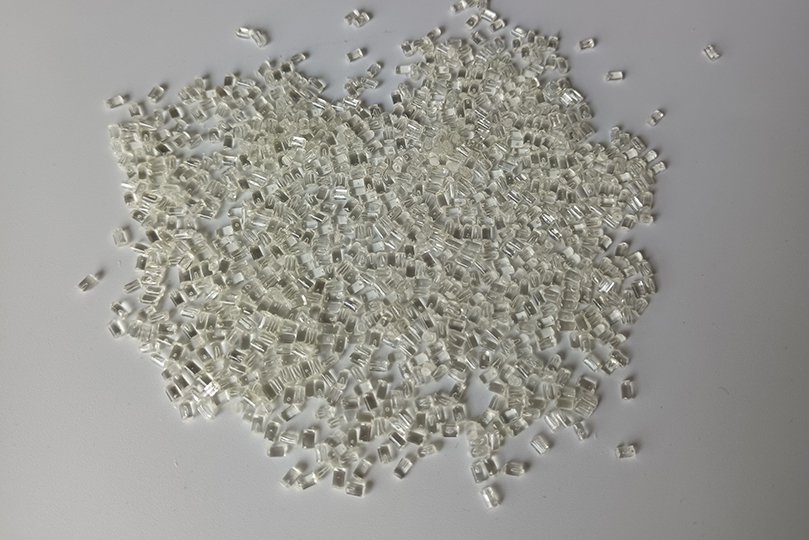

What is PSU?

Polysulfone (PSU) is a high-performance thermoplastic polymer known for its excellent chemical stability, mechanical strength, and thermal resistance. PSU’s structure includes a repeating sulfone group that imparts durability and heat resistance, making it an ideal material for demanding applications such as water filtration.

Key Properties of PSU for Water Filtration Membranes

-

Superior Chemical Resistance One of the most critical factors in water filtration is the ability to withstand chemical exposure. Filtration membranes often come into contact with various chemicals, including cleaning agents and contaminants present in untreated water. PSU offers outstanding chemical resistance to acids, bases, and solvents, ensuring the filtration membranes can operate effectively without degrading or losing performance over time.

-

High Thermal Stability PSU boasts excellent thermal stability, allowing membranes to perform at high temperatures without losing structural integrity. Many water filtration processes, particularly those involving industrial or municipal applications, require membranes that can withstand elevated temperatures. PSU’s ability to maintain its mechanical properties in high-temperature environments makes it an ideal material for these challenging conditions.

-

Mechanical Strength and Durability The mechanical strength of PSU ensures that membranes made from this material can endure physical stress, pressure, and prolonged use. Filtration membranes are subject to constant water flow, pressure differentials, and potential fouling, all of which can degrade weaker materials over time. PSU’s robustness helps extend the life of water filtration membranes, reducing the need for frequent replacements and lowering maintenance costs.

-

Excellent Hydrolytic Stability One of PSU’s standout properties is its hydrolytic stability—its resistance to water-based degradation. Over time, exposure to water can cause some plastics to break down or become brittle. PSU, however, maintains its structural integrity even in continuous contact with water, making it an ideal material for long-lasting water filtration membranes.

-

Biocompatibility PSU is known for its biocompatibility, making it safe for use in filtration systems that process drinking water. Many filtration applications, especially in medical and food industries, require materials that do not leach harmful substances. PSU’s inert nature ensures that it does not introduce any toxic compounds into the water, ensuring the safety and purity of the filtered water.

Applications of PSU Water Filtration Membranes

The unique combination of properties that PSU offers has made it a popular choice for a variety of water filtration applications:

-

Municipal Water Treatment: In large-scale water treatment facilities, PSU membranes are used to filter contaminants from water to provide safe drinking water for communities. The material’s resistance to fouling and high durability ensures long-term performance in municipal water filtration systems.

-

Industrial Water Treatment: Industrial applications often deal with harsh conditions, such as exposure to aggressive chemicals and high temperatures. PSU’s chemical and thermal resistance make it suitable for use in industrial water filtration systems, where reliable performance is critical.

-

Desalination: As the demand for freshwater increases, desalination processes are becoming more common. PSU membranes can be used in reverse osmosis and nanofiltration systems to remove salt and other impurities from seawater, providing an efficient solution for producing potable water from seawater.

-

Medical Applications: PSU’s biocompatibility extends its use to the medical field, where it is used in dialysis and other medical water purification systems. The material’s stability and resistance to chemical degradation make it a trusted choice for filtering water in sensitive medical environments.

Advantages Over Other Materials

Compared to alternative membrane materials such as polyvinylidene fluoride (PVDF) and polypropylene (PP), PSU provides several advantages. While PVDF offers good chemical resistance, it does not match PSU’s thermal stability. Similarly, PP is less chemically resistant and lacks the mechanical strength that PSU offers. PSU provides an excellent balance between chemical resistance, durability, and performance, making it a superior choice for high-performance water filtration membranes.

Conclusion

PSU’s outstanding combination of chemical resistance, thermal stability, mechanical strength, and hydrolytic stability makes it an ideal material for high-performance water filtration membranes. Its ability to perform in a wide range of conditions, from industrial settings to municipal water treatment plants, demonstrates its versatility and reliability. As clean water becomes an increasingly important global resource, PSU will continue to play a crucial role in advancing water filtration technology and ensuring the safety and purity of our water supply.

At Shengwen, we provide customized services for your personal demands,such as the resin's colors, color and dimension of boards or rods, and other performance design.