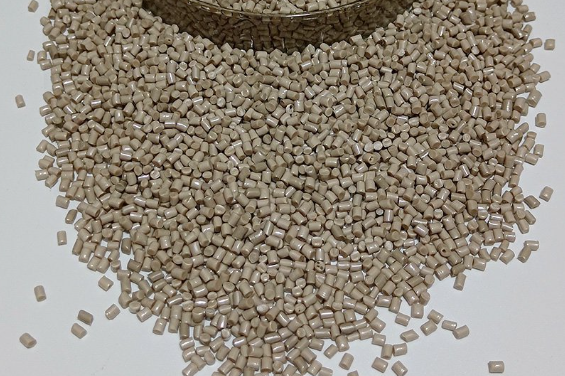

PEEK is an ultra-high-performance special engineering plastic developed by the British Imperial Chemical Industries Company (ICI) in 1978. Since PEEK is an aromatic crystalline thermoplastic polymer material, its melting point is 334℃. It has high strength, high-temperature resistance, impact resistance, flame retardant, acid and alkali resistance, hydrolysis resistance, wear resistance, fatigue resistance, radiation resistance and excellent electrical properties. In most cases, it can replace metals, alloys, ceramics and other materials, currently mainly used in aerospace, automotive industry, electrical and electronic and medical machinery fields.

Energy saving, weight reduction, cost minimization, and product performance maximization have always been important indicators for the development of automobiles. Especially in people's pursuit of comfort and stability of cars, the weight of corresponding equipment such as air conditioners, safety airbags, electric windows and ABS braking systems is also increasing.

Auto parts use PEEK with good friction resistance, mechanical properties and easy processing performance, which not only greatly reduces processing costs and weight, but also ensures long-term service life. PEEK can replace metals in the manufacture of automotive ABS anti-lock braking devices, seals, gaskets, bearings and other components, and can be used in automotive transmission systems, braking systems, steering systems, seat systems and so on.

Aerospace is the earliest application field for PEEK. The particularities of the aviation sector require flexible, low-cost processing and lightweight materials that are resistant to harsh environments. PEEK has many performance advantages in this field, such as high-temperature resistance, excellent machining, radiation resistance, low smoke, flame retardant, non-toxic, corrosion resistance, hydrolysis resistance, etc. Therefore, PEEK can replace aluminum and other metal materials to manufacture various aircraft parts, which can reduce weight by up to 70% compared with metal, and improve fuel efficiency.

In terms of electronic appliances, PEEK resin has excellent electrical properties and is a good electrical insulator. It can still maintain good electrical insulation in harsh working environments such as high temperature, high pressure, and high humidity, widely used in computers, mobile phones, circuit boards, printers, light-emitting diodes, batteries, switches, connecting plugs, hard drives and other electronic equipment.

PEEK has the advantages of non-toxicity, excellent biocompatibility, lightweight and corrosion resistance, etc. It is a kind of bioprosthetic material with great potential.

In addition to being used for high sterilization requirements and repeated use of surgery, dental equipment and some compact medical equipment, the most important use of PEEK is the artificial bone that can replace metal construction and is organically combined with the body, which is the closest to human bones material.

Tuntunplastic is a comprehensive company specializing in the production, sales and service of special engineering plastic, including PPSU, PSU, PES, PA12, PEEK, and PEBA, which are used in many fields. If you are in need of PEEK materials, please get in touch with us today!

By continuing to use the site you agree to our privacy policy Terms and Conditions.