Engineering plastics are plastics that can be used as engineering materials and replace metals to make machine parts. Engineering plastics have excellent comprehensive performance, high rigidity, low creep, high mechanical strength, good heat resistance, and good electrical insulation. They can be used in harsh chemical and physical environments for a long time and can replace metals as engineering structural materials, but the price is more expensive.

Engineering plastics can be divided into general engineering plastics and special engineering plastics. The main varieties of the former are polyamide, polycarbonate, polyoxymethylene, modified polyphenylene ether and thermoplastic polyester; the latter mainly refers to engineering plastics with heat resistance above 150°C, and the main varieties are polyimide, polyphenylene sulfide, polysulfones, aromatic polyamides, polyarylates, polyphenylene esters, polyaryletherketones, liquid crystal polymers and fluororesins, etc.

(1) Compared with general plastics, it has excellent heat resistance and cold resistance, and has excellent mechanical properties in a wide temperature range, and is suitable for use as structural materials;

(2) Good corrosion resistance, less affected by the environment, and good durability;

(3) Compared with metal materials, it is easy to process, has high production efficiency, and can simplify procedures and save costs;

(4) Good dimensional stability and electrical insulation;

(5) Lightweight, high specific strength, and outstanding friction reduction and wear resistance.

Engineering plastics are widely used in electronics, automobiles, construction, office equipment, machinery, aerospace and other industries. It has become an international trend to replace steel and wood with plastic. Engineering plastics has become the fastest-growing field in the plastics industry in the world today. Its development not only supports the national pillar industries and modern high-tech industries but also promotes the transformation of traditional industries and the adjustment of product structure.

The application of engineering plastics in automobiles is increasing, mainly for bumpers, fuel tanks, instrument panels, body panels, doors, lamp covers, fuel pipes, radiators, and engine-related parts.

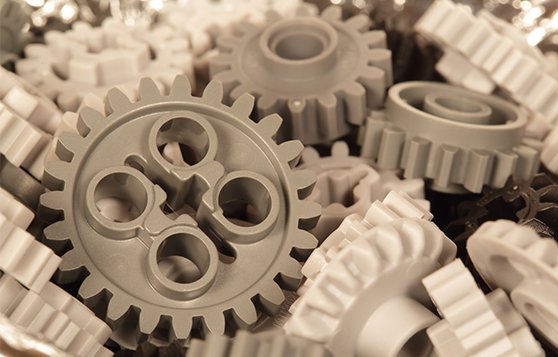

In machinery, engineering plastics can be used on mechanical parts such as bearings, gears, screw nuts, seals, and mechanical structural parts such as housings, covers, handwheels, handles, fasteners, and pipe joints.

In electronics, engineering plastics can be used for insulating materials such as wire and cable coating, printed circuit boards, insulating films, and structural parts of electrical equipment.

In household appliances, engineering plastics can be used in refrigerators, washing machines, air conditioners, televisions, electric fans, vacuum cleaners, electric irons, microwave ovens, rice cookers, radios, combined audio equipment and lighting appliances.

In the chemical industry, engineering plastics can be used in chemical equipment such as heat exchangers, chemical equipment linings, and in chemical pipelines such as pipes and fittings, valves, and pumps.

Tuntunplastic is a comprehensive company specializing in the production, sales and service of special engineering plastic, including PPSU, PSU, PES, PA12, PEEK, and PEBA, which are used in many fields. If you are in need of engineering plastics, kindly get in touch with us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.