Special engineering plastics are a new generation of high-performance polymer materials driven by the social needs of the Cold War. They were called high-temperature-resistant polymer materials in the early days, and they are usually called special engineering plastics or high-performance plastics. High-Performance Polymer refers to a new type of high-performance polymer new material with high comprehensive performance that can be used for a long time at a temperature higher than 150 °C.

Special engineering plastics have many characteristics that other materials cannot have at the same time, such as high-temperature resistance, fatigue resistance, corrosion resistance, wear resistance, radiation resistance, high strength, high toughness, excellent electrical properties, and good dimensional stability. It is an indispensable revolutionary material in the fields of national defense, aviation, aerospace, shipbuilding, etc., or in the development of high-tech in electrical appliances, electronic communications, automobiles, medical equipment, petrochemicals, etc.

The research and development of special engineering plastics began in the 1960s. The R&D was mainly concentrated in developed countries such as Europe, the United States, and Japan. China's special engineering plastics started in the mid to late 1990s. At present, there is still a certain gap compared with developed countries.

It mainly includes PEEK, PEKK, PEK, PEKEKK, etc., which have excellent high temperature resistance, mechanical properties, radiation resistance and chemical resistance, and are widely used in automobiles, electronic appliances, aerospace, medical and health and other fields.

It mainly includes ordinary bisphenol A polysulfone (PSF), biphenyl polyethersulfone (PPSU), polyethersulfone (PES), etc., which have the advantages of heat resistance and heat and humidity resistance, and excellent mechanical properties and processing properties, mainly used in machinery industry, electronic appliances, transportation, medical equipment and other fields.

It is one of the organic materials with the highest heat resistance. It has excellent high and low-temperature resistance, solvent resistance, radiation resistance, mechanical properties and other characteristics. It is mainly used in aerospace, electronic appliances, energy, electricity, machinery, electronic display and other fields.

It mainly includes PA4T, PA6T, PA9T, PA10T, PA11T and PA12T, etc., which have the advantages of high-temperature resistance, corrosion resistance and low water absorption, and are mainly used in the fields of electronic appliances and automobile industry.

It mainly includes thermotropic liquid crystal TLCP and lyotropic LLCP, which have high strength, high modulus, high-temperature resistance, low moisture absorption, good dielectric properties, high flame retardancy, chemical corrosion resistance, low linear expansion coefficient, high dimensional precision, good dimensional stability and other excellent performance, mainly used in electronic appliances, consumer electronics, national defense, aerospace, automotive, medical and other fields.

It has the characteristics of high-temperature resistance, radiation resistance, high flame retardancy, high dimensional stability, good solvent resistance, chemical corrosion resistance and excellent electrical properties. It is mainly used in automobiles, electronic appliances, filter materials and other fields.

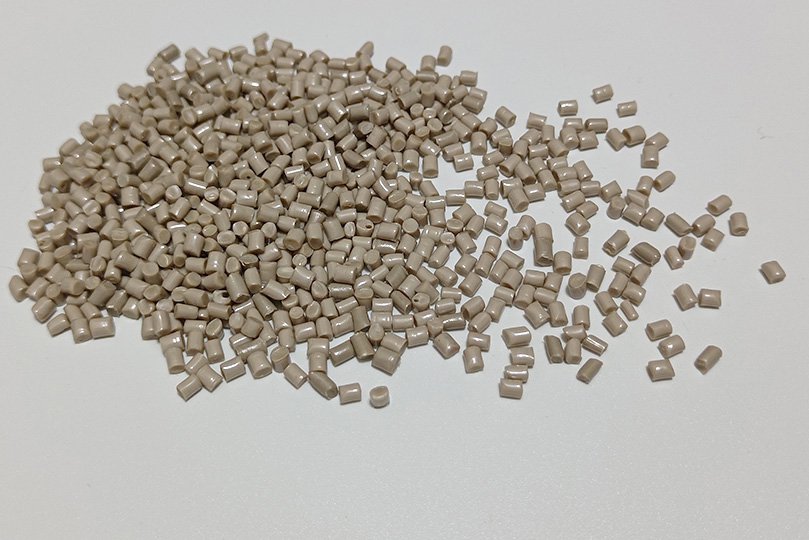

Tuntunplastic is a comprehensive company specializing in the production, sales and service of special engineering plastic, including PPSU, PSU, PES, PA12, PEEK, and PEBA, which are used in many fields. If you are in need of special engineering plastics, kindly get in touch with us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.